This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful. See our privacy policy.

News

Discover how hydrogen fuel cells are revolutionizing aviation, offering zero-emission solutions. Explore the critical role of hardware simulation testing and developing.

The introduction of EA to the Tektronix team provides the company with expanded solutions, leveraging Tektronix’s industry-leading oscilloscopes and isolated probes, EA’s high-efficiency power supplies and electronic loads, and Keithley’s high-precision source meters and instrumentation.

Battery Testing for Off-Road Electric Vehicles

April 09, 2024

The market for electric vehicles is growing rapidly, including for off-highway electric vehicles (EVs). And while battery life for passenger EVs gets most of the industry hype, designing and testing long-lasting and durable batteries for the off-road vehicle sector is just as critical, and even more complex for design engineers to consider.

Mistakes to Avoid When Integrating a Battery Test System

February 07, 2024

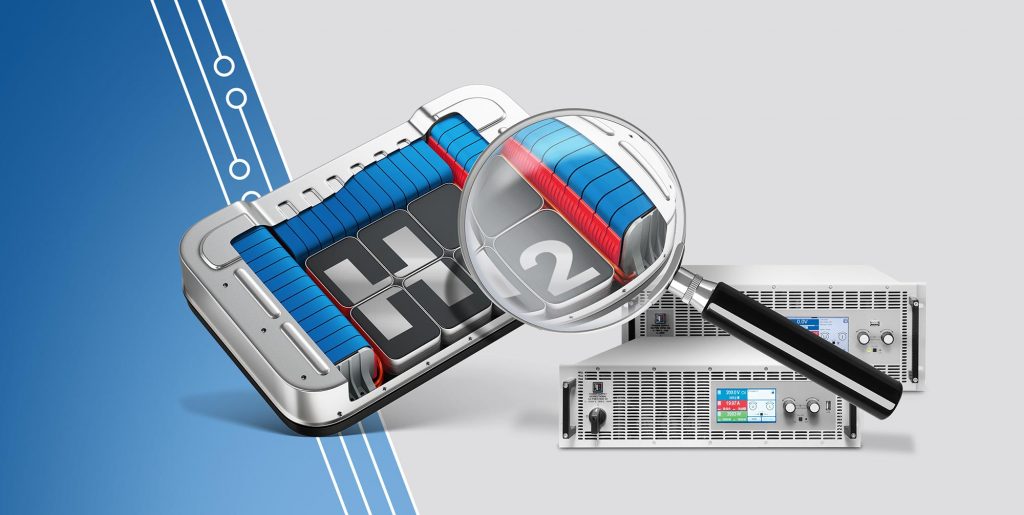

It’s not easy to configure a battery cycle test system for EV batteries and similar high-power batteries. Many components, such as contactors, power supplies, cyclers, data acquisition and sensors, need to be made into a system using software and challenging connections.

In addition to future power requirements, the survey covers power supply performance requirements, the need for communication with power supplies in remote locations, and the importance of energy efficiency.

Battery Test Lab Design Fundamentals

September 27, 2023

Physical testing of actual batteries is crucial because digital twins cannot reliably replicate the potential sources of trouble. “To understand how a battery is going to degrade over time, we have to test them,”

The 10300 Series ATE system offers industry-leading power density: 300 kW in a single 42U-high rack that consumes only 6.5 square feet of production-floor space, one-third the space of the leading brand.

Testing Batteries for an Evolving World

August 03, 2023

Demand for electric vehicles is amping up. Every one of these vehicles needs large batteries, and the industry is responding by building plants. Energy.gov forecasts that by 2030 electric vehicle battery manufacturing capacity in North America will grow 20 times, eventually supporting 10-13 million electric vehicles per year.

How Power Supplies Add Innovation to the Battery Boom

July 24, 2023

Amid the current boom times in global battery business development and applications, it pays to keep in mind advances being made and support being given by the non-battery equipment sector.

Programmable power supplies are power sources that can be remotely controlled and programmed through various digital interfaces or analog inputs to provide a specific output voltage, current and power level. Programmable power supplies are commonly used in electronics manufacturing, battery testing and research and development to provide precise and accurate power to their respective applications. They are also popular in automation applications, in which they can be programmed to cycle through different output levels depending on the application’s needs.

EA Elektro-Automatik announces the opening of its new Technology and Training Center in Troy, MI. The center will offer product demos, training and pre-purchase testing available to companies in the nearby region and countrywide.

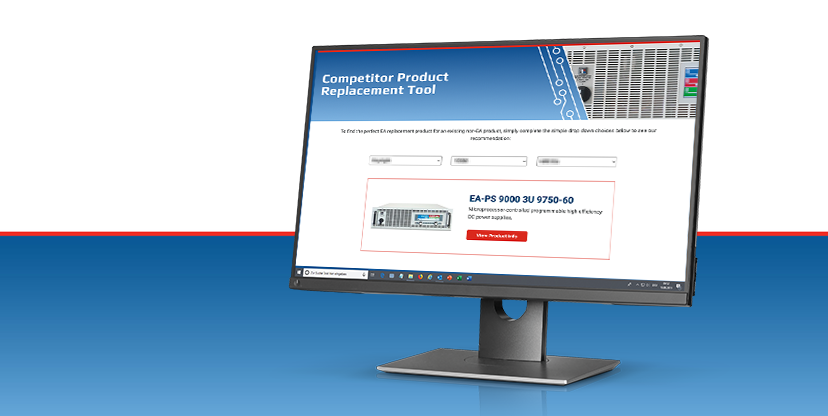

The innovative new Competitive Product Replacement Tool enables customers to find comparable EA product solutions for major brands, making it simple to identify the comparable competitor power supply.

EA Elektro-Automatik Expands Its 10000 Series

March 24, 2022

The new product launch includes four classes of new 2U models offering a greater range of power from 600 W to 3 kW. The models provide voltages from 10 V extending up to 1500 V, and provide output current up to 120 A.

The EA-Axiom partnership allows Axiom Test Equipment to introduce high quality EA Elektro-Automatik power supplies and electronic loads to users with shorter-term projects and those who want to ‘try before buying’.

Joint effort will help improve efficiency and power capacity for EV battery testing to address climate change

EA Elektro-Automatik, líder global en equipos de ensayo de potencia DC, pone a su disposición una potente serie de fuentes de alimentación DC y cargas DC regenerativas ideales para el ensayo con células de combustible.

EA Elektro-Automatik Offers Bidirectional DC Power Supplies and Regenerative DC Loads for Testing Fuel Cells

Discarded batteries: check residual capacities with EA devices or discharge completely

Baterías desechadas: compruebe las capacidades residuales con los equipos de EA o descárguelas completamente.

Empresa ÖKOPROFIT (ECOPROFIT) excepcional

March 01, 2021

EA Elektro-Automatik refuerza su compromiso ecológico. Productos regenerativos y un programa medioambiental que reducen el uso energético y los costes operativos

EA Elektro-Automatik Expands its Ecological Engagement

March 01, 2021

Regenerative products and an environmental program reduce energy usage and operating costs