This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful. See our privacy policy.

THE BATTERY TESTER WITH SINGLE AND TRIPLE OUTPUT

EA-BT 20000

High-Current with 3 channels available

High-Precision for measuring voltage and current

High-Speed with maximized throughput

EA-BT 20000

Benefit from battery tests with available triple output

High-Current

- Triple model with 3 channels at 600 A each, or parallel for 1800 A

- Power capacity to 30 kW and voltage up to 920 V

- Triple model can simultaneously test up to three battery packs with a power of 4 kW/channel, 6 kW/channel and 10 kW/channel

High-Precision

- For measuring State of Health (SOH) and End of Life (EOL)

- Measurement of voltage and current with the required accuracy and performance

- Reproducibility and reliability of data

High-Speed

- Maximized throughput and 1 ms communication speed

- Cost savings due to less equipment for instrumentation of the tests

The power of three available channels

- Cell, module or pack tests up to 1.92 MW

- As an integrated solution

2-quadrant devices for charging and discharging high capacity battery packs - For a wide range of applications

For battery testing, battery simulation and battery recycling

Single and triple high performance applications

![]()

Battery tests

- Testing of the electrical characteristics of a battery

- SOH (State-of-health) for Second-life-Classification and End-of-Life (EOL) testing

- In an automated test system or in an integrated battery test

![]()

Battery simulation

- Simulation of batteries as single cells, modules or packs

- For optimal design of the energy storage system as well as the components to be tested

- When reproducible data is required

- With overcurrent protection (OCP) for safe function and protection of the connected loads

![]()

Battery recycling

- For the complete discharge of the battery before final recycling

- Maximum possible deep discharge at high charge current, even at voltages below 2 V

The added values

![]()

Regenerative:

Save energy costs

- Energy recovery with an efficiency of up to more than 96%

- Significant savings of kilowatt hours

- No conversion of energy into heat / No cost-intensive air conditioning

- Fast amortization of the EA-BT 20000 units

![]()

Interface and control flexibility:

For automated testing

- Software EA-Power Control and EA-Battery Simulator

- For configuration and test procedure without programming language

- Via connection with PC or programmable logic controller (PLC)

- Two operative modes: SCPI commands for program control from a PC/ModBus commands for program control from a PLC

- Standard interfaces

![]()

Safety Sense:

Test safely

- Galvanically isolated share bus for parallel operation

- Master-auxiliary bus for parallel operation

![]()

Autoranging:

Flexible output levels

- Wide voltage, current and power range

- For a wider field of operation than conventional battery testers

EA-BT 20000 measures internal and external sense independently

BT 20000 features active pre-charge, contactor control and Safety Sense.

BT 20000 measures the internal and external sense completely independently

- Ability to actively pre-charge the power supply

- Offering dynamic sense regulation

- Ensures the best current rise time in dynamic tests

- Cable and connection check for cable losses or bad connections

- Additional error modes:

- COW (Cable overload warning)

- COP (Cable overload protection)

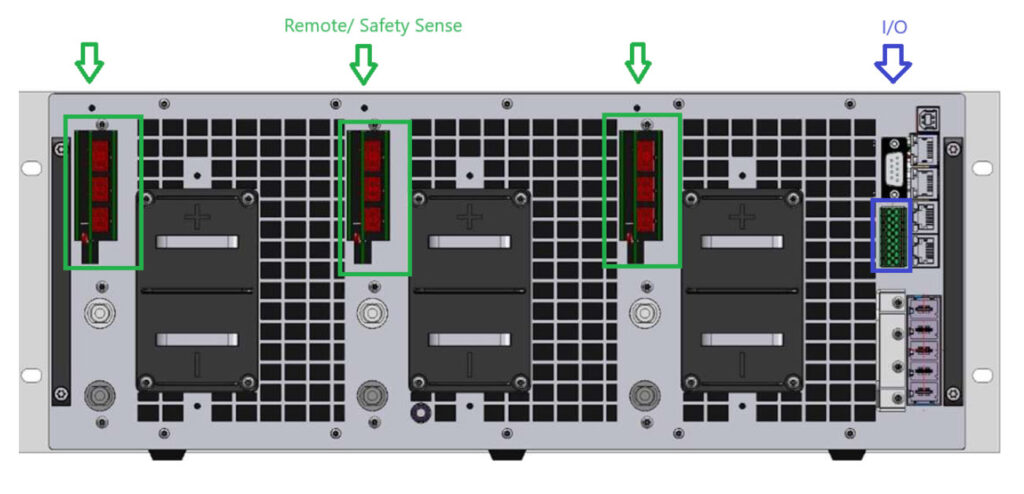

Each area in green is the remote sense for each channel

Control output to manage DC contactors of a test stand

Advantages of managing the external DC contactor via BT 20000:

- Active pre-charge will prevent unwanted inrush currents when the test object gets connected

- Safer operation of the battery test stand – Safety Sense avoids faulty connections as well as polarity reverse faults

- “Zero current turn-off” on DC contactor will save the lifetime of the DC contactor

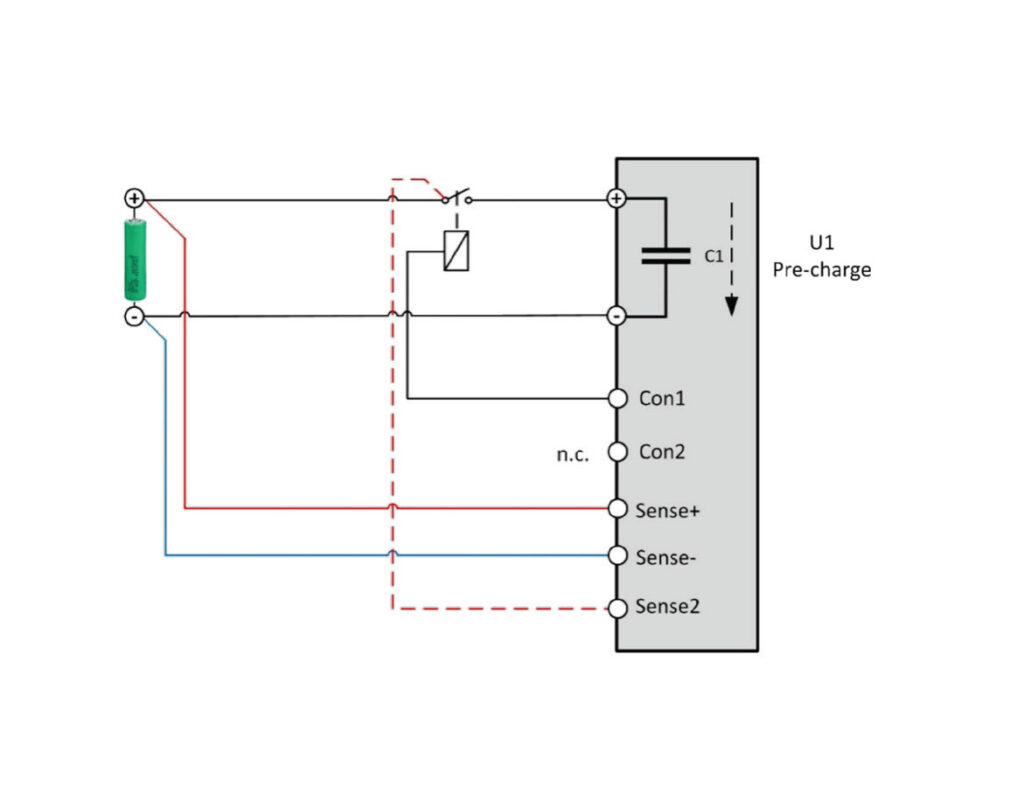

Active pre-charge prevents unwanted inrush currents

If a test object is connected to the test device, an inrush current occurs when the battery cell puts energy into the output capacitor of the test device. This is hazardous for several reasons:

- The current could damage the battery or the test equipment

- Potentially dangerous and alarming sparking at the terminal when connecting

- Existing DC contactors will wear down quickly whenever there is a peak current

Therefore, pre-charge of the output capacitor is required. BT 20000 offers an automated active pre-charge. Due to completely independent internal and external sense measurements, the device will pre-charge its internal capacitor without using any energy from the battery under test. The BT 20000 then closes the external DC contactor once the active pre-charge is finished.

Safety Sense avoids faulty connections

The safety sense is intended to be a fixed installed part of the test stand. It does not change or move around when a new test object is connected. As this part of the installation is always fixed, it is not compromised by potential operator errors such as:

- Operator might put test object and sense in reverse

- Operator might mix up different sense channels

- Sense might fall apart during test

Since the Safety Sense can detect these issues, the added benefits result in complete operational safety.

The features at a glance:

- Wide range input: 208 V – 480 V, +10%, 3ph AC

- Active power factor correction, typical 0.99

- Battery tester, 2-quadrant for charging and discharging

- In discharge mode regenerative with energy recovery into the grid

- Very high efficiency of up to more than 96%

- Voltage from 0 – 10 V up to 0 – 920 V

- High power with up to 10 kW per channel

- Currents from 0 – 40 A up to 0 – 600 A per channel

- Flexible power regulated DC output/input stages (autoranging)

- Control modes CV, CC, CP, CR with fast transition digital control, high resolution with 16 bit ADCs and DACs, control speed selection: Normal, Fast, Slow

- Galvanically isolated share bus for parallel operation

- Master-auxiliary bus for parallel operation

- Built-in interfaces with 1 ms communication speed

- Typical battery tester functionality integrated

- Integrated battery test mode, battery simulation

- Command languages and drivers: SCPI and ModBus, LabVIEW, IVI

| Series | Power Connection | Voltage | Current | Power | Datasheet | Get Quote |

|---|---|---|---|---|---|---|

| EA-BT 20000 Triple 4U | 0 to 920V | 40A per channel to 600A per channel | 4kW per channel-10kW per channelW | Get a Quote | ||

| EA-BT 20000 4U | 0 to 2000V | 1000A | 30kW | Get a Quote | ||

| EA-BT 20000 3U | 0 to 2000V | 0 to 600A | 0-15kW | Get a Quote |