This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful. See our privacy policy.

EA-POWER RACKS FOR ELECTROLYSIS PLANTS

Reliable, fail-safe DC programmable power supplies

The solution: Fail-safe high-power rocks from EA

Highest power density for reliable hydrogen production

While the demand for green hydrogen from electrolysis plants was once limited to a few regions, the use and production of hydrogen energy is now found worldwide. With more industries and consumers turning to hydrogen as their energy source, plants must continuously produce hydrogen and turn to the most fail-safe DC programmable power supply technology on the market – the EA-PU 10000 6U and EA-PUB 10000 6U programmable power supplies. Packaged as a fully turnkey, modular rack solution, EA Elektro-Automatik’s Modular Power Rack systems provide a variety of critical benefits to hydrogen energy electrolysis facilities:

Modular EA-Power Racks Benefits

- Fail-safe power supplies

Based on EA’s PU and PUB supply instruments, the turnkey modular rack solution allows fast changes or simplified system expansion to drastically reduce downtime

- Up to 3.84 MW output power

When four racks are paralleled together

- Communication and Ethernet interfaces

Including CAN, CANopen, EtherCAT, RS232, Profibus, Profinet, Modbus, Ethernet

- True autoranging

For more testing capability with just one device

- Air- or water-cooled versions

To adapt to any environment

- Plug-and-play

Programmed, prewired and ready to place into production

Modular Power Racks from EA

Reliable power for electrolysis production

Avoid shutdown and long repair delays with EA’s modular design. Designed to facilitate fast changeouts or simplified system operation, production plants avoid past challenges from rigid, monolithic energy systems. In addition, reconfiguration is automatic if needed to ensure continued energy for hydrogen production.

Programmable DC Power Supplies for EA Turnkey Power Racks

The EA-PU 10000 6U and EA-PUB 10000 6U fit perfectly into EA Power Racks for the highest power density in the smallest footprint, ideal for high-power hydrogen production needs. Up to eight units fit into a 42U rack, customized depending on application requirements.

True Autoranging, Convenient Touchscreen Operation and Remote User Interfaces

Quickly test and program with just one device using EA’s true autoranging feature, saving capital costs and critical rack space. Other convenient features include the touchscreen operation for quick, intuitive, remote user interfaces for safe distant operation.

EA Programmable Power Racks for Fail-safe Hydrogen Production

High operational value. Dependable power.

Scalable

Customize EA-Power Racks to adapt to voltage and current requirements and parallel units for power up to 3.84 MW

Automation

Seamlessly integrate into electrolysis plant production with remote functionality for safe operation.

Service-friendly

Integrated Ethernet interfaces allow for remote maintenance and diagnostics. Modular design automatically reconfigures as needed for reliable, steady power.

Compact

Highest-power density with the smallest footprint in the industry. Additional features, including true autoranging, negates the need for additional equipment.

Plug and Play

EA turnkey racks require no programming, wiring or set-up before use and arrive fully tested.

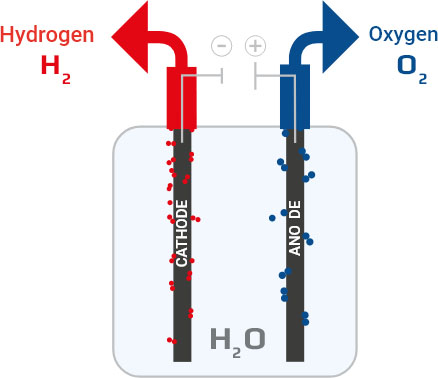

Programmable DC Power Supply Solutions for Hydrogen Production

Electrolyser

High-quality programmable DC power supplies reduce CAPEX by improving production efficiency

Rectifier

High voltage/high current regenerative load solutions recover 96% of energy and return it to the grid