This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful. See our privacy policy.

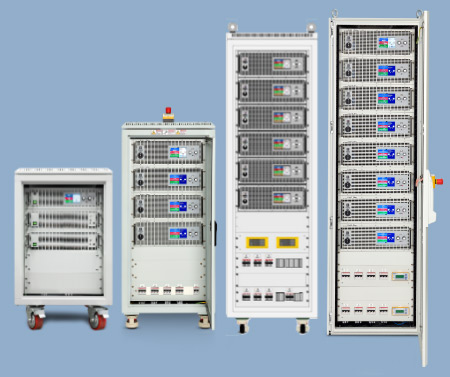

EA Turnkey DC Power Racks

High-performance cabinet systems for air-/water-cooled supplies

Select devices and integrate into the rack

New high-performance systems are constantly being developed for the electrification of the world. Associated with this is the testing requirement for the battery packs, fuel cell stacks, solar systems or electrolysis systems (or: electrolysers). With the turnkey EA rack system you have the possibility to select the suitable devices for your tests and simulations and to integrate them into the EA turnkey power racks.

Power supplies and loads

Configure 3U, 4U and 6U devices into 42U, 38U and 24U rack systems. Combine EA-10000 and EA-10000 Industrial series programmable power supplies, bidirectional power supplies, or regenerative loads. System performance can be increased by connecting devices in parallel. In a 42U rack with 5 units of 60 kW you can reach 300 kW, for the maximum power of 3.84 MW you can connect up to 64 units in 13 racks.

EA rack systems: A lot of power. Lots of flexibility. Many advantages.

Modules & Power

- Modular rack systems with 42U, 38U and 24U

- Integrable devices in height units 3U, 4U and 6U

- 300kW in only one 42U rack, containing 5 6U’s at 60kW each

- 3.84 MW in only 13 racks with up to 64 devices

Devices & Series

- Integrable device types:

- Programmable power supplies

- Bidirectional power supplies

- Regenerative electronic loads

- Integrable series:

- EA-10000 and EA-10000 Industrial

Efficiency & Applications

- Minimal footprint, rack depth only 1000 mm/19″ cabinets

- Supplied as turnkey EA rack systems

- Ideal for DC high power applications

Configure your suitable EA rack system

Choose your Unit

Choose your Rack

Choose your Enhancements

Optional equipment for your EA rack systems:

- Water cooling

- NS Protection

- Isolation Monitor

- DC Contactor

- DC Copper bar

- Control Switch

- Ethernet Switch

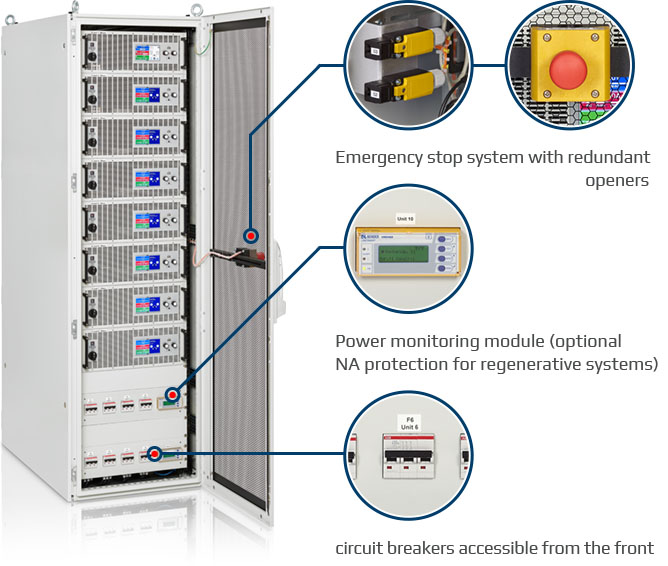

Safe, reliable, and efficient

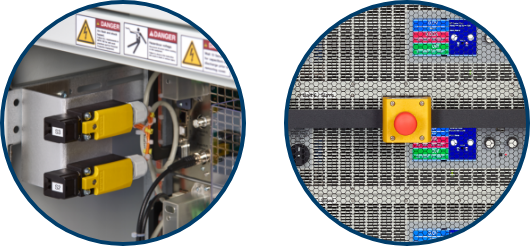

Integrated safety system

Each modular EA rack system includes a safety system integrated as standard. It complies with the EN 60204-1 standard and is prepared for connection to a 3-phase 400 V mains supply. The rack systems are equipped as standard with a 2-channel emergency stop system, including an emergency stop button and door contact switches at the rear door of the 19″ cabinet. A central safety relay monitors and controls the entire safety system and switches off the redundant AC contactor if necessary. In addition, all devices in the rack and the entire cabling of the rack system are protected by fuses.

Sustainable efficiency benefits

Autoranging

“Autoranging” is a term when a programmable DC source automatically offers a wide output range of both voltage and current to maintain full power output across a wide operation range.

See Products

Power regeneration

With an efficiency up to over 96%, the absorbed energy is fed back into the grid – Environmentally friendly and cost-saving.

See Products

8 Options for EA rack system equipment

Choose the right EA rack system equipment for your applications

01 Water Cooling

In order to be able to use the EA rack systems in as many environments as possible, they are available as air-cooled standard version and as water-cooled version.

Water cooling includes the water-cooled equipment and the pre-installed and tested water distribution system in the rack system, which allows quick and easy connection to the building services.

Choose water cooling for environments where waste heat must not be released to the immediate environment and noise must be reduced.

02 NS Protection

Network and supply protection (NS) increases safety for regenerative systems when EA rack systems are equipped with regenerative loads such as PUB, PSB, PUL or ELR. In the rack system, the NS protection from a well-known supplier monitors the grid for the feed-in of generation and regenerative plants.

The module acts on the emergency stop chain and switches off the entire rack in the event of a mains fault. Islanding (disconnection of the power grid from the connection to the larger power grid) is prevented.

03 Isolation Monitor

The EA rack system is optionally equipped with the insulation monitor of a renowned supplier. This monitors the insulation resistance of the DC output against protective earth. The module acts on the emergency stop chain and switches off the entire rack system in the event of an insulation fault. This increases the safety of the operated system.

04 DC Contactor

DC contactors are used to increase safety and are mounted between the DC output of the EA rack system and the device under test (DUT). In the rack, the DC contactors are integrated into the emergency stop chain. In the event of an emergency stop situation, the DC contactors break the connection between the rack system and the DUT. This provides clear isolation and prevents unwanted currents from flowing between the rack and the DUT.

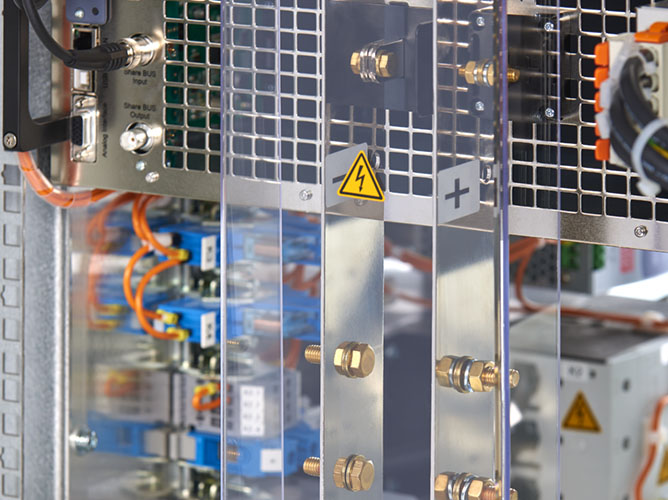

05 DC Copper bar

DC copper busbars are used to connect the DC output of multiple devices within an EA rack system to parallelize power and increase rack performance accordingly.

A central connection point is provided to connect the DC output of the entire rack to the intended application. The DC copper busbars are supplied pre-assembled and are designed for specific applications.

06 Control Switch

If the EA rack system is equipped with a control switch, the complete rack can be switched on and off with it.

The control switch acts on the redundant AC contactors of the rack system and speeds up or simplifies handling. The control switch can be secured with a padlock.

07 Ethernet Switch

The 19″ Ethernet switch from a renowned supplier with 24 ports is installed in the EA rack system. By using the switch, a multi-channel rack system can be operated via only one external Ethernet interface.

The individual devices are connected internally between the switch and the rack system’s built-in devices. This reduces the number of cables required for the supply in the system and the cabling effort in general.

08 Signal Lamp

The Advantages of the Turnkey Rack System in 2 Minutes

Device Types and Series

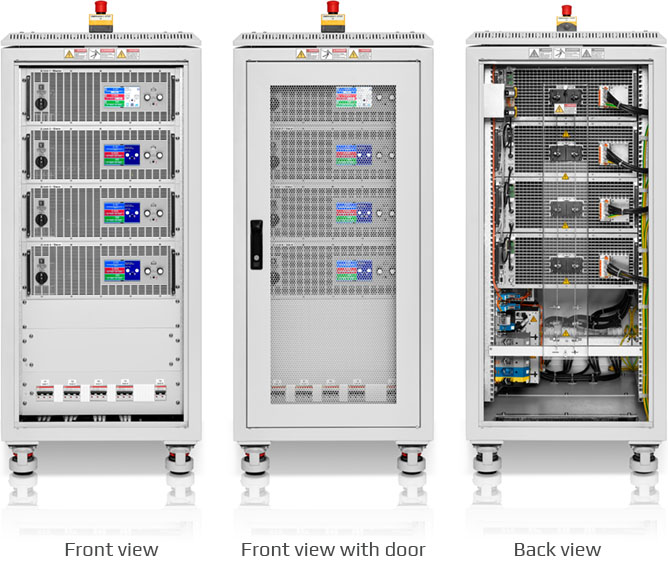

24U Height DC Rack Systems

Power range from 15 – 120kW

Features

- For 380 V, 400 V, and 480 V AC

- With bidirectional power supplies with regenerative power supply (PSB) or power supplies (PSI)

- Intuitive operation through the multilingual color TFT touch panel

- Extensive function generator

- Application for photovoltaics, battery, fuel cell and many more

- Extensive protective functions (OVP, OCP, OT…)

- USB, Ethernet, and analog interface as standard

- Plug & Play slot for digital interfaces

- All interfaces galvanically isolated

- Optional: water cooling

- Optional: NA protection (1 with emergency stop system

- Optional: emergency stop system without NA protection

- Control software EA Power Control

- Simulation software EA Battery Simulator (PSB)

- LabVIEW VI User Library

- IVI driver package

- SCPI and ModBus protocol

- 19″ cabinet in 15 HE

- Expandable to up to 4 devices per cabinet

| Equipment with series 9000 |

|---|

| Power ranges: 15 to 45 kW |

| Programmable DC laboratory power supplies: PS 9000 / PSE 9000 / PSI 9000 |

| Programmable DC electronic loads: EL 9000B / ELR 9000 |

| Programmable bidirectional DC laboratory power supplies: PSB 9000 |

| Height units: 3 U |

| Equipment with series 10000 |

|---|

| Power ranges: up to 120 kW |

| Programmable DC laboratory power supplies: PSI 10000 |

| Programmable DC electronic loads: ELR 10000 |

| Programmable bidirectional DC laboratory power supplies: PSB 10000 |

| Height units: 4 U |

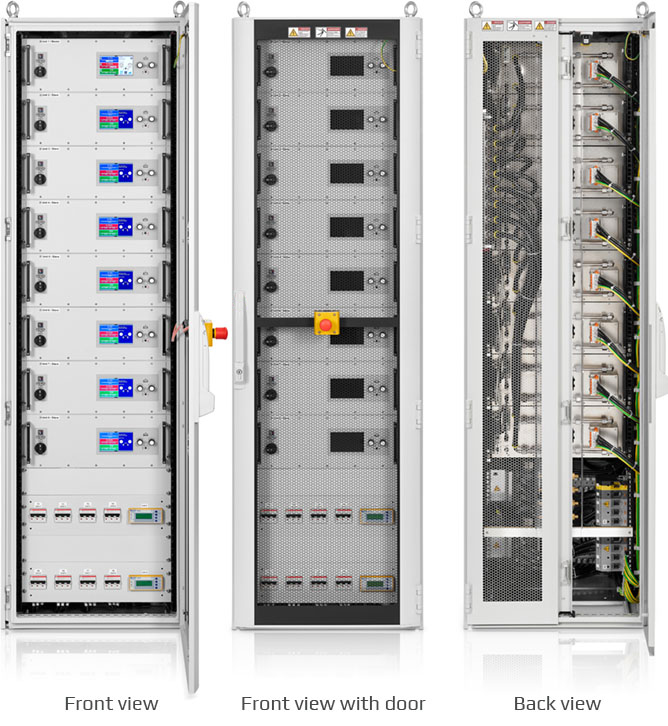

42U Height DC Rack Systems

Up to 1920kW in 19″ cabinets

Features

- For 380 V, 400 V, and 480 V AC

- With bidirectional power supplies with regenerative feedback (PSB 10000) or loads with regenerative feedback (ELR 10000) or power supplies (PSI 10000)

- Rated power up to 240 kW per cabinet or up to a maximum of 1920 kW as master-auxiliary system

- Nominal voltages up to 2000 V

- 60 V configurations for SELV

- Intuitive operation through the multilingual color TFT touch panel

- Extensive function generator

- Application for photovoltaics, battery, fuel cell and many more

- Extensive protective functions (OVP, OCP, OT…)

- USB, Ethernet, and analog interface as standard

- Plug & Play slot for digital interfaces

- All interfaces galvanically isolated

- Built according to EN 60204-1 (Machinery Directive)

Various options:

- Emergency stop system

- Insulation monitoring

- Mains and system protection (for regenerative devices)

- Water Cooling

| Equipment with series 9000 |

|---|

| Power ranges: 15 to 45 kW |

| Programmable DC laboratory power supplies: PS 9000 / PSE 9000 / PSI 9000 |

| Programmable DC electronic loads: EL 9000B / ELR 9000 |

| Programmable bidirectional DC laboratory power supplies: PSB 9000 |

| Height units: 3 U |

| Equipment with series 10000 |

|---|

| Power ranges: up to 300 kW |

| Programmable DC laboratory power supplies: PSI 10000 |

| Programmable DC electronic loads: ELR 10000 |

| Programmable bidirectional DC laboratory power supplies : PSB 10000 |

| Height units: 4 U |

Multi-product DC Rack / Cabinet Systems

Up to 1920 kW in 19″ cabinets

| System | 240 | 480 | 720 | 960 |

|---|---|---|---|---|

| Voltage | 60 – 2000 V | 60 – 2000 V | 60 – 2000 V | 60 – 2000 V |

| Current | 40…8000 A | 360…16000 A | 680…24000 A | 1000…32000 A |

| Power | (1 – 8) x 30 kW | (9 – 16) x 30 kW | (17 – 24) x 30 kW | (25 – 32) x 30 kW |

| AC-connections | 2 | 4 | 6 | 8 |

| Max. AC-Current | 448 A (2 x 224 A) | 996 A (4 x 224 A) | 1344 A (6 x 224 A) | 1792 A (8 x 224 A) |

| System | 1200 | 1440 | 1680 | 1920 |

|---|---|---|---|---|

| Voltage | 60 – 2000 V | 60 – 2000 V | 60 – 2000 V | 60 – 2000 V |

| Current | 1320…40000 A | 1640…48000 A | 1960…56000 A | 2280…64000 A |

| Power | (33 – 40) x 30 kW | (41 – 48) x 30 kW | (49 – 56) x 30 kW | (57 – 64) x 30 kW |

| AC-connections | 10 | 12 | 14 | 16 |

| Max. AC-Current | 2240 A (10 x 224 A) | 2688 A (12 x 224 A) | 3136 A (14 x 224 A) | 3584 A (16 x 224 A) |

| Systemcode | 240 | 480 | 720 | 960 | 1200 | 1440 | 1680 | 1920 |

|---|---|---|---|---|---|---|---|---|

| Number of Cabinets | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| Network connection type | 2 x 3 phase three-phase current per cabinet (L1, L2, L3, N, PE) | 2 x 3 phase three-phase current per cabinet (L1, L2, L3, N, PE) | 2 x 3 phase three-phase current per cabinet (L1, L2, L3, N, PE) | 2 x 3 phase three-phase current per cabinet (L1, L2, L3, N, PE) | 2 x 3 phase three-phase current per cabinet (L1, L2, L3, N, PE) | 2 x 3 phase three-phase current per cabinet (L1, L2, L3, N, PE) | 2 x 3 phase three-phase current per cabinet (L1, L2, L3, N, PE) | 2 x 3 phase three-phase current per cabinet (L1, L2, L3, N, PE) |

| Mains voltage | 380 / 400 / 480 V (with installed NA protection 400 V) ∓ 10%, 45 – 66 Hz, PF > 0.99 | 380 / 400 / 480 V (with installed NA protection 400 V) ∓ 10%, 45 – 66 Hz, PF > 0,99 | 380 / 400 / 480 V (with installed NA protection 400 V) ∓ 10%, 45 – 66 Hz, PF > 0.99 | 380 / 400 / 480 V (with installed NA protection 400 V) ∓ 10%, 45 – 66 Hz, PF > 0.99 | 380 / 400 / 480 V (with installed NA protection 400 V) ∓ 10%, 45 – 66 Hz, PF > 0.99 | 380 / 400 / 480 V (with installed NA protection 400 V) ∓ 10%, 45 – 66 Hz, PF > 0.99 | 380 / 400 / 480 V (with installed NA protection 400 V) ∓ 10%, 45 – 66 Hz, PF > 0.99 | 380 / 400 / 480 V (with installed NA protection 400 V) ∓ 10%, 45 – 66 Hz, PF > 0.99 |

| System height | 24 HE or 42 HE, depending on the number of units per cabinet | 24 HE or 42 HE,depending on the number of units per cabinet | 24 HE or 42 HE, depending on the number of units per cabinet | 24 HE or 42 HE, depending on the number of units per cabinet | 24 HE or 42 HE, depending on the number of units per cabinet | 24 HE or 42 HE, depending on the number of units per cabinet | 24 HE or 42 HE, depending on the number of units per cabinet | 24 HE or 42 HE, depending on the number of units per cabinet |

| System width | 60 cm | approx. 120 cm | approx. 180 cm | approx. 240 cm | approx. 300 cm | approx. 360 cm | approx. 420 cm | approx. 480 cm |

| Number of possible devices | 8 | 9 – 16 | 17 – 24 | 25 – 32 | 33 – 40 | 41 – 48 | 49 – 56 | 57 – 64 |

| Max. achievable power | 240 kW | 480 kW | 720 kW | 960 kW | 1200 kW | 1440 kW | 1680 kW | 1920 kW |

Close-up of the water distribution of a cabinet with eight units and water cooling (240 kW system), DC bus

Close-up view from DC bus (24U cabinet system)

Close-up view of the share bus and master-auxiliary bus

Find the Right Tool

Power Selection Guide

What MUST you consider when choosing a Programmable DC Power Supply? What output is right for your application? How much power you you pay for without over specifying? Download our Guide to help you navigate the many considerations when specing the right DC power supply.

Download Power Guide