This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful. See our privacy policy.

Battery Test and Simulation Expertise

We can source and sink power at 96% efficiency

Batteries have become a huge part of our daily lives. Electrical and electronic devices are becoming increasingly mobile, meaning that batteries are required to power everything including computers, drones, automobiles, and buses. The batteries used in these products require significant testing during development and production to ensure they will meet real-world demands.

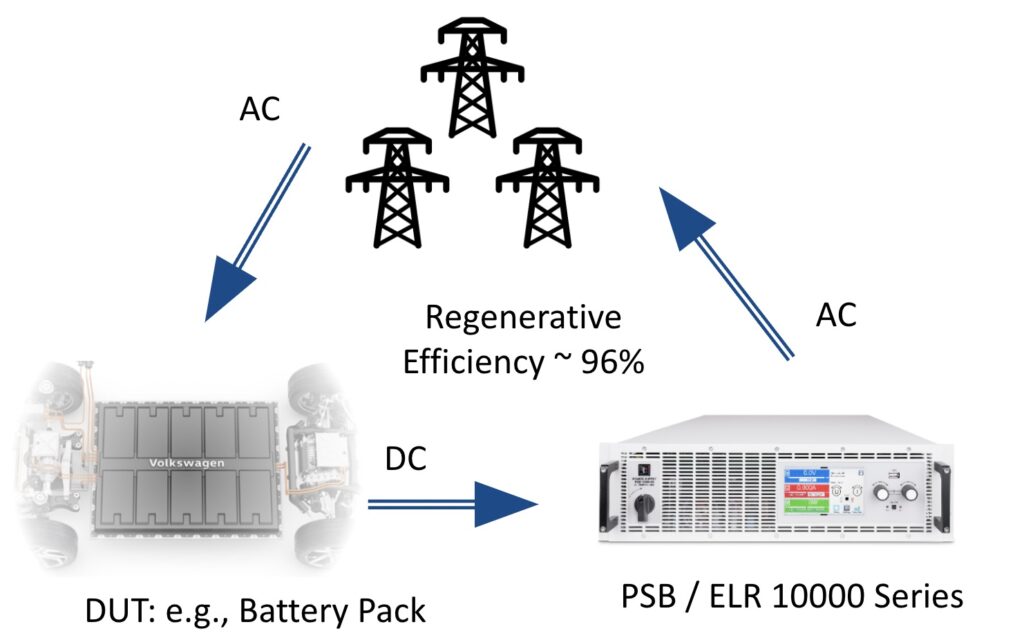

Traditionally, engineers used programmable DC power supplies to charge batteries and resistive or electronic loads to discharge them. Today, a single instrument—the bidirectional, regenerative power supply—can perform both tests. Using a bidirectional, regenerative power supply saves equipment costs and valuable rack space, as well as energy costs by regenerating the energy from a discharging battery back into the local grid.

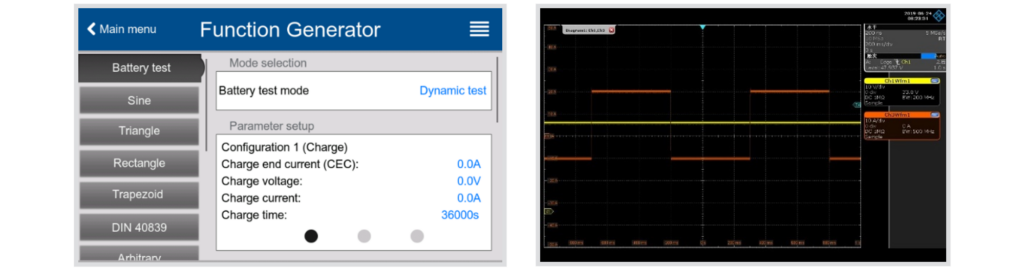

The EA Elektro-Automatik PSB Series can transition seamlessly between providing DC power to charge batteries and sinking DC power during discharge cycles. The energy it sinks from a discharging battery can then be put back into the local grid, saving both energy and heating costs for the testing facility. And, EA’s DC power supplies and loads come standard with pre-installed battery test software for both lithium-ion and lead-acid batteries to make setting up and running your battery tests even easier.

See our battery testing and simulation products in action!

Application Solutions

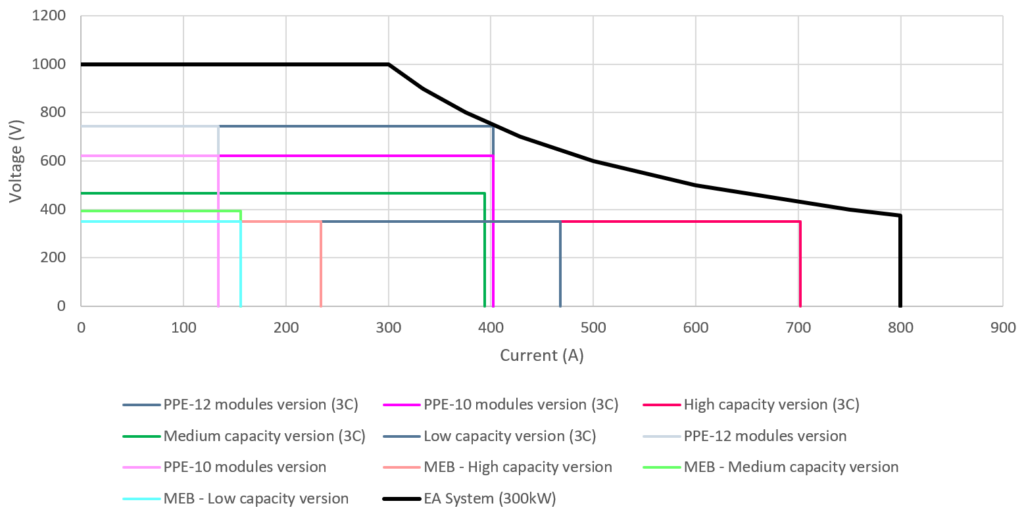

PSB 10000 series – The perfect Bidirectional Test Platform

Regenerative and Efficient

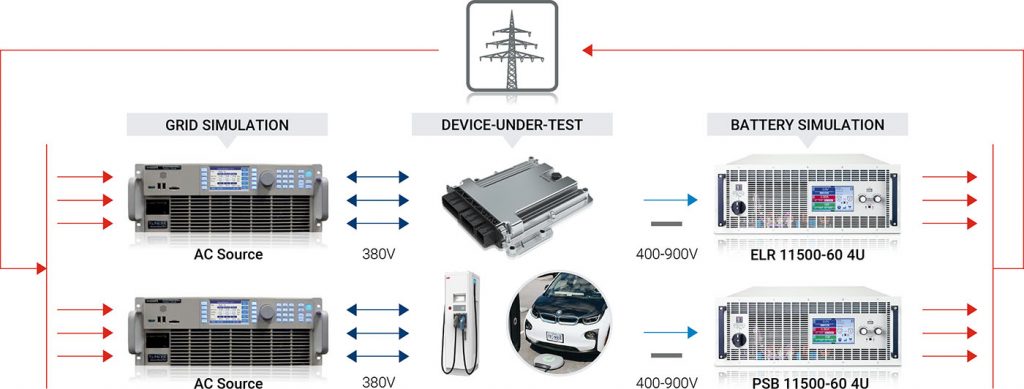

PSB being used to simulate a battery in an electric vehicle

Battery Recycling

Sustainability in electromobility is a major challenge

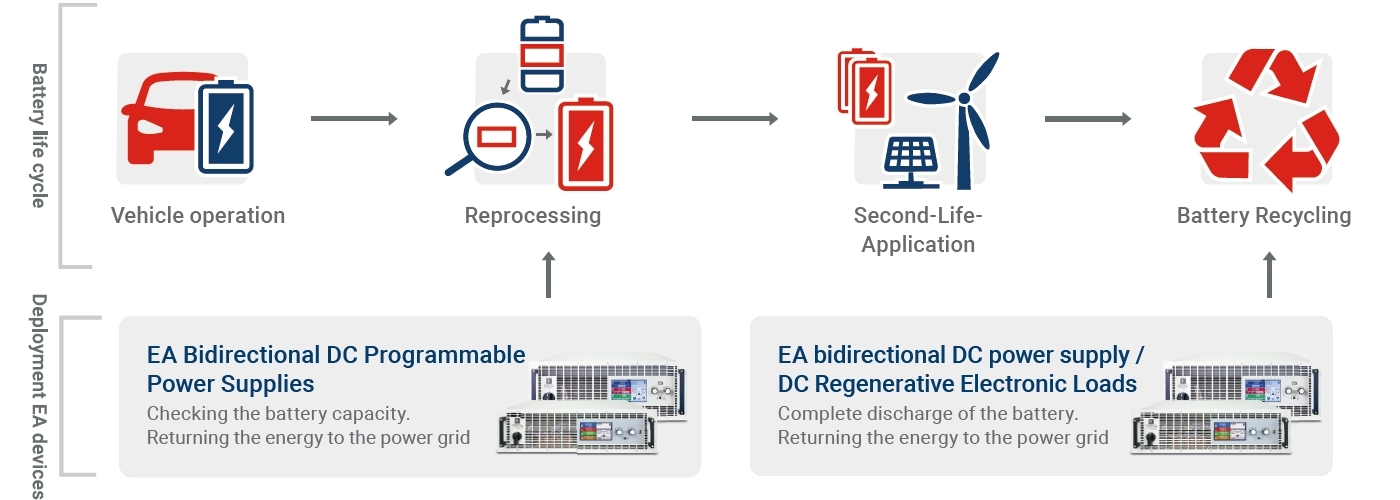

To make electromobility sustainable, second-life concepts and efficient recycling of lithium-ion batteries and lithium-ion polymer batteries will play a key role in the very near future. Completely new industries and companies are emerging to take on this task.

EA-BT 20000 TRIPLE

Optimize your battery recycling with EA

Regenerative loads and bidirectional programmable DC power supplies from EA Elektro-Automatik make your battery recycling:

- efficient

- flexible

- economical

- safe

- sustainable

Second-life use

Bidirectional DC lab power supplies test the remaining capacity of your batteries

The primary goal is to find a second use for the batteries from electromobility after they have been used in the vehicle (second-life use). For example, as energy storage for solar power or wind energy. When testing the remaining capacity, the battery is first fully charged and then discharged in a controlled manner. The capacity (SOC) and state of aging (SOH) are measured and the energy is fed back into the power grid with an efficiency of over 96%.

The bidirectional programmable DC power supplies from EA Elektro-Automatik are ideally suited for this process.

Final recycling

Electronic loads with mains feedback for the complete discharge of your accumulators

After the second-life cycle, the rechargeable batteries are subjected to final recycling. This process attempts to recover as many components of a lithium-ion battery as possible as raw material for new batteries. Before the batteries are disassembled into their individual parts, they must be fully discharged. This is done in order to avoid the risk of contact-hazardous voltage or fire and to use the residual energy still stored in the battery.

EA Elektro-Automatik’s regenerative electronic loads are a very efficient solution for this purpose.

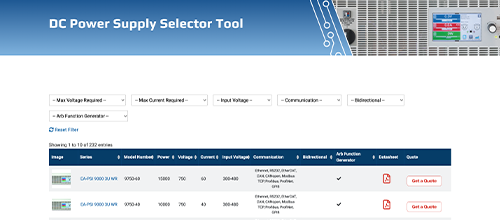

Find the Right Tool

Power Selection Guide

What MUST you consider when choosing a Programmable DC Power Supply? What output is right for your application? How much power you you pay for without over specifying? Download our Guide to help you navigate the many considerations when specing the right DC power supply.

Download Power GuideFAQs

A battery simulation creates an electronic circuit that mimics a real battery’s voltage and current behavior. The simulator uses electronic components and circuitry to reproduce the characteristic voltage profiles and current responses of different battery types and chemistries. This activity enables users to test and evaluate the ways that various devices or systems respond to simulated battery characteristics without the need for actual batteries.

A car battery simulator, or the act of simulating a car battery, involves replicating the voltage and current characteristics of the particular automotive battery in question. Electric circuitry and components can mimic a typical care battery’s voltage discharge profile and current output. Factors taken into consideration often include voltage levels during starting, charging and normal operation. The goal is to create a test setup that can accurately emulate a car battery’s behavior for various automotive electrical system testing and development purposes.

A battery cell simulator is a device used in research and testing to emulate the behavior of individual battery cells. It replicates the voltage, current and impedance characteristics of specific battery chemistries and cell types. Battery cell simulators offer a powerful tool that enables operators to study and evaluate battery performance, management systems and the impact of different cell behaviors on battery packs or systems without the need for the physical battery cells.

A programmable power supply is ideal for simulating a battery because it allows the operator to control voltage and current levels precisely to replicate various battery characteristics. To simulate a battery with a power supply, set the power supply voltage to match the voltage of the battery that requires simulation. Make sure the power supply can provide the required current and voltage levels. Adjust the power supply settings as required to mimic the battery behavior, such as voltage fluctuations or discharge characteristics.

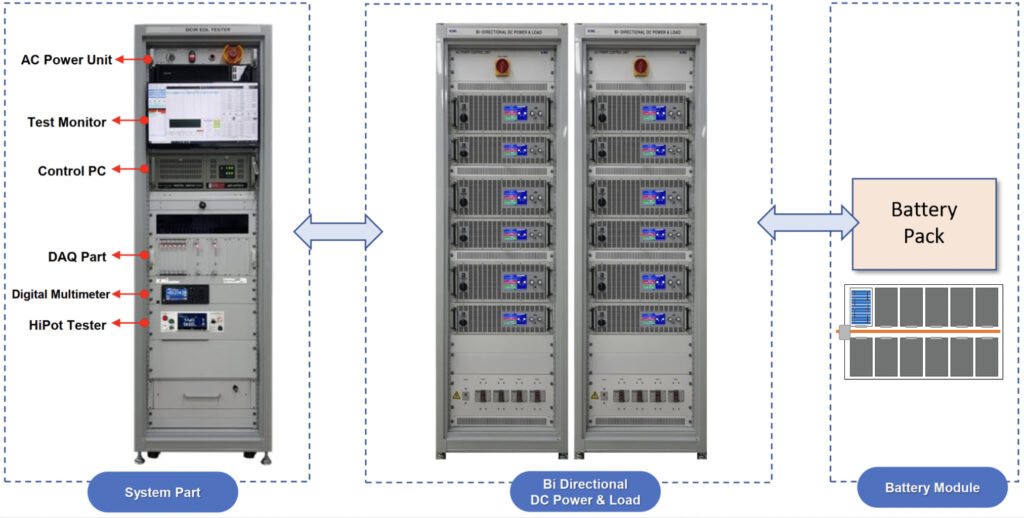

A battery testing system is a specialized equipment setup used to assess batteries’ performance, capacity and durability. The setup typically includes the proper instruments and software to monitor voltage, current, temperature and other required parameters. This allows for comprehensive testing and analysis of battery behavior under different conditions.

A battery testing system enables research, development and quality control processes as applied to batteries used in various applications, from consumer electronics to industrial automation and electric vehicles.

A battery test provides critical information about a battery’s performance and health. The test results can indicate the battery’s capacity, including the amount of energy the battery can both store and deliver, its state of charge and the rate at which the battery charges and discharges. Additionally, battery tests can help detect signs of degradation, such as reduced capacity or increased internal resistance. These indicators represent the battery’s overall health and potential lifespan.

The battery tests help operators assess a battery’s reliability, safety and suitability for a specific application. Industries that rely on battery testing and test results range from consumer electronics to electric vehicles, industrial automation and renewable energy platforms.

The three basic battery tests can be summarized as:

- Capacity Test: This measures a battery’s ability to store and deliver a specific amount of energy, usually expressed in ampere-hours (Ah) or watt-hours (Wh).

- Voltage Test: This monitors the battery’s voltage to assess its state of charge and performance. This test can also detect overcharging or undercharging conditions.

- Load Test: This test evaluates a battery’s performance under a specific load to check its ability to deliver power when needed. The test assesses the battery’s voltage stability and capacity under load.

The most accurate way to test a battery is by combining the results from testing multiple characteristics or parameters, including capacity testing, voltage monitoring and load testing. By analyzing the battery’s performance under various conditions and monitoring its capacity, voltage stability and response to loads, the operator can comprehensively assess the battery’s health and reliability. Advanced battery testing systems that combine these methods and employ precision instruments tend to provide the most accurate results.

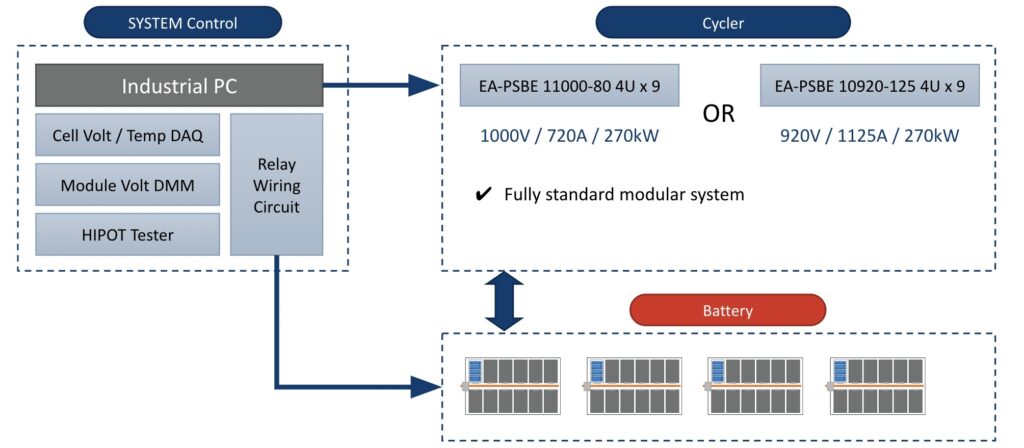

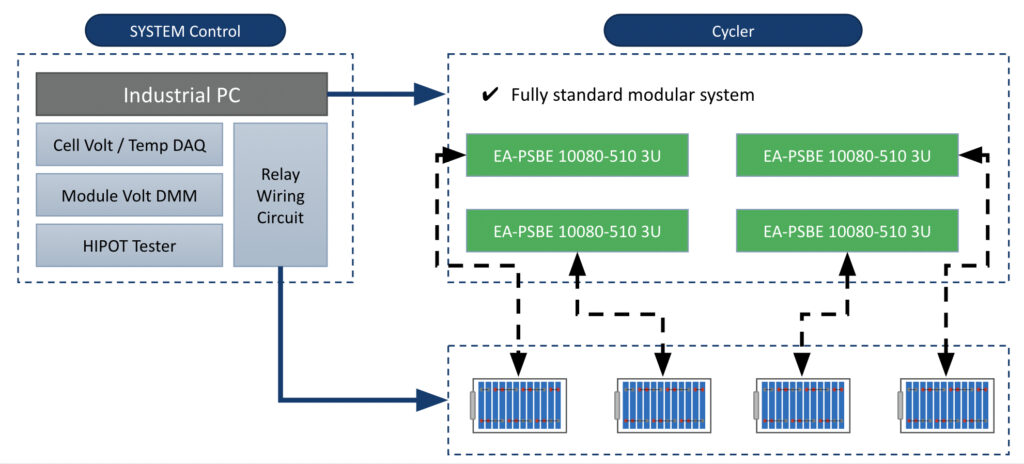

An EV battery cycler is specialized EV battery testing Equipment used to simulate the charging and discharging cycles of an electric vehicle (EV) battery pack under controlled conditions.

EV battery packs require this specialized EV battery testing device compared to other battery testing systems because an EV battery pack involves high-voltage systems, complex thermal management and specific protocols. These EV testing methods replicate electric vehicles’ unique operating conditions and requirements, which are distinct from traditional battery testing for smaller-scale applications.

The specialized system or device allows for the precise and repetitive EV testing standards for EV batteries to evaluate their performance, capacity and durability over a range of operating conditions. Test results are critical to ensure the safe use and operation of EV battery packs by identifying potential issues and monitoring performance, validating the battery’s ability to withstand the demanding conditions of EV usage.

A battery cycle, in the context of battery usage, refers to the complete charge and discharge of a battery. When a battery goes through one full charge and discharge cycle, this completes one cycle of use. A battery management system often keeps track of the number of cycles a battery has experienced during its lifetime. This cycle count supplies a critical metric to help assess a battery’s lifespan and its remaining capacity. Batteries typically have a limited number of cycles they can undergo before their performance starts to degrade significantly.

A battery cycle test is a procedure that involves repeatedly charging and discharging a battery to assess its performance, capacity and longevity over multiple charge/discharge cycles. This test helps determine how well a battery maintains its capacity and how many cycles it can endure before experiencing degradation. This test helps determine or evaluate the suitability of the battery for various applications.

Equipment used to test a battery includes a battery tester or analyzer, which may consist of a load back, voltage and current sensors, and a control system. These will be used for battery testing along with specialized instruments like multimeters, power supplies and impedance analyzers.

Simulating a car battery requires a DC power supply with a voltage rating equivalent to that of a typical car battery (around 12 volts) or the voltage necessary to match that of the battery under test. Connect the power supply to the vehicle’s electrical system, ensure the correct polarity and set the voltage output to mimic the battery’s state of charge.

Optionally, the operator can add a resistor load to simulate the battery’s internal resistance and monitor the power supply’s current output to replicate the behavior of a real car battery under different conditions.

To check a battery with equipment, you can use a battery tester or multimeter to the corresponding battery terminals, ensuring proper polarity. The equipment will provide voltage readings, which can indicate the battery’s state of charge. Load tests can assess the battery’s capacity and health by recording voltage drop under load.

A battery simulator, often used for testing electronic devices, works by emulating or mimicking the behavior of a real battery. The simulator generates a controlled voltage or current output that mimics the characteristics of various types of batteries, such as their voltage levels, internal resistance and response to changing loads. This simulation allows electronic devices to be tested under different battery scenarios without the need for actual batteries, providing a reliable and repeatable testing environment.

Electric vehicle (EV) batteries are tested through a series of rigorous procedures to ensure their safety, efficiency, and longevity. The main aspects of testing include capacity and performance testing, safety testing, lifestyle testing and regulatory compliance testing. EV battery testing equipment measures charging and discharging cycles, energy density and short circuit tests.

Comprehensive EV battery testing is crucial to ensure that EV batteries are reliable, safe, and efficient, balancing performance and longevity.