This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful. See our privacy policy.

Programmable DC power supplies have long been instrumental in power electronics and battery testing. These supplies are extensively used for performance testing and product characterizations. However, a common issue arises when dealing with excess energy generated during burn-in tests, battery cycling or discharging energy storage systems before shipment. Traditionally, this surplus energy is dissipated as heat using resistive load banks or electronic loads.

While seemingly simple, this approach brings about thermal management and noise challenges, making it less straightforward than it appears.

This begs the question: can this surplus power be recycled and put to use within the facility? In recent years, there has been a growing push for industrial facilities to become more eco-friendly and operate with greater energy efficiency. Regenerative electronic loads present an energy-saving solution as they redirect the load power back to the utility, offering a greener alternative to resistive load banks.

Ready to Get Started? Request a Quote

The potential energy savings can be substantial, particularly for larger industrial facilities with extensive testing operations. For instance, Elektro-Automatik’s (EA) regenerative electronic loads boast an impressive 96% efficiency, allowing businesses to recycle the majority of the otherwise wasted power. This marks the evolution of DC programmable power supplies, wherein all the energy is returned to the local power grid. In this blog, we will explore the amount of energy savings an industrial facility can achieve by switching to a regenerative load.

Dissipating excess energy: resistive load banks and electronic loads

DC load banks serve the purpose of simulating electrical loads to test power sources and ensure they meet specifications or manufacturer ratings. These loads accurately mimic the behavior of an actual load during testing without connecting to the load’s normal operating system. The excess energy is typically dissipated as heat. Load banks can be resistive, reactive (inductive or capacitive) or capacitive in nature.

The most common type, the resistive load bank, simulates the load by converting electrical energy into heat using power resistors. During testing, the load bank is connected to the output of a power source (generator, battery, amplifier, PV system) instead of its regular load. The load bank presents electrical characteristics similar to the standard operating load while dissipating the power output usually consumed by the load.

The power is converted into heat using a heavy-duty resistor or a bank of resistive heating elements. This method replicates, verifies and proves real-life demands on critical power systems. Load banks are also used with intermittent renewable power sources like windmills to shed excess power that the grid cannot absorb.

Resistive load banks offer a cost-effective solution when noise, workspace and efficiency are not major considerations for the application.

The wasteful applications: discharging energy storage devices and burn-in testing

Regardless of the load’s programmability, it must still dissipate excess energy as heat. This task is not always straightforward and often requires convective cooling through forced air (fans) or liquid immersion (water tank). The common dissipative load is the resistive load bank, where power resistors burn energy in the form of heat, wasting 100% of the energy. These resistive load banks can be loud and add significant ambient noise to the factory environment. Moreover, active cooling systems add to the energy burden, as they require additional power for air conditioning, fans or cooling tanks.

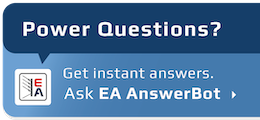

Image of a resistive load bank with DC fans, adding significant noise to the factory environment.

Certain tests require a significant amount of power sinking. For example, industrial testing of batteries and fuel cells necessitates discharging the cells before shipment to ensure safe integration into a stack or larger system.

Burn-in testing for various devices under test (DUTs), such as DC power supplies, motors, inverters, micro-inverters, batteries and fuel cells, also demands fan-cooled resistive load banks. These burn-in cycles run for several days continuously and ensure the longevity of the DUT under normal, accelerated or extreme environmental conditions before performance testing.

These labs are costly to operate, and many facilities run testing operations around the clock. For instance, battery validation often involves parallel testing of numerous devices. Making use of every last amp-hour that the battery offers during its lifetime is crucial, and the testing setup involves DUTs, environmental chambers, automated test equipment (ATE) and test software/analytics.

Embracing greener solutions: regenerative electronic loads

In testing technologies like batteries, traction controllers, bidirectional EV chargers and fuel cells, both a source and a sink are necessary. For example, testing a battery requires charging and discharging to examine bidirectional energy transfer during regenerative braking. Traditionally, these tests are conducted using a programmable DC supply and either an electronic load or a passive load (resistive bank). Instead, regenerative electronic loads can convert discharge power (P = V * I) into usable electricity for the facility.

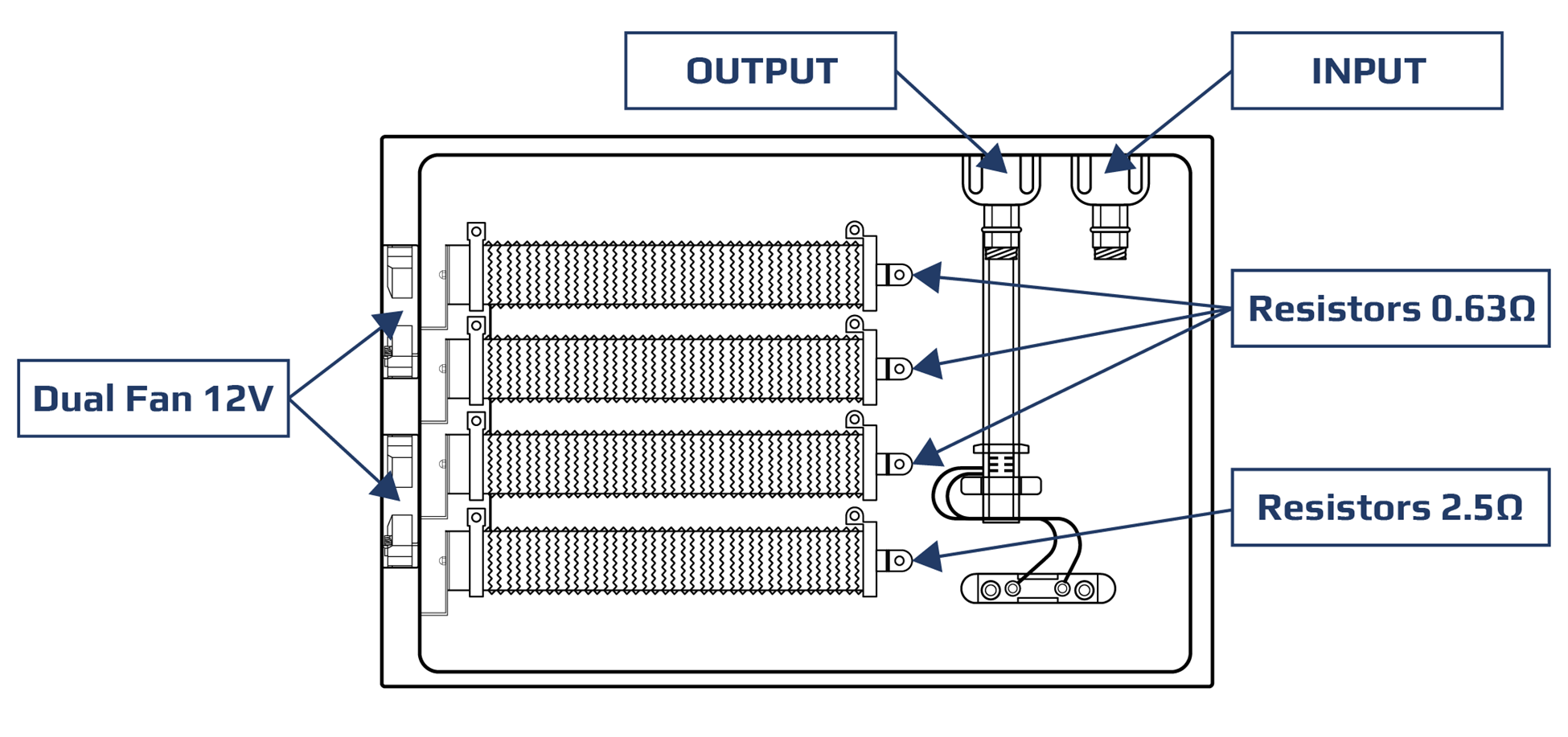

Energy flow with the regenerative power supply

This approach offers cost-effective advantages in two ways:

- Reducing total power demand and associated electrical costs.

- Keeping devices cooler, which reduces energy consumption for facility cooling.

This allows more flexibility in planning, upgrading or rearranging laboratory or manufacturing workspaces.

The advantages of EA’s bidirectional power supplies

EA’s bidirectional power supplies (PUB series) integrate regenerative electronic loads and programmable power supplies into a single asset. Instead of wasting power, a regenerative load feeds the excess energy back into the local grid. The energy passes through a DC-DC converter into a DC-AC inverter (current source), which synchronizes with the distribution grid to recycle power.

Besides the regenerative load feature, these power supplies also incorporate true autoranging capability, allowing them to mimic a wide range of voltages and currents from a single solution. Additionally, they have a built-in arbitrary waveform function generator, simplifying test setups and enabling a range of dynamic testing applications.

The power supplies can easily swap between common digital industrial interfaces like RS232, Profibus, CAN/CANOpen, DeviceNet, Modbus, Ethernet, Profinet and EtherCAT through Anybus communication.

The regenerative ROI

Implementing regenerative electronic loads presents a significant return on investment (ROI). For instance, a facility sinking 20 kW of power with extensive testing operations can save substantially. Using the average US electricity rate of $0.3 per kilowatt-hour (kWh) for a 40-hour workweek.

Here are the savings associated with this scenario:

- $124,416 total yearly usage savings

- Over 98% reduction in usage

- ELR purchase ROI of 24 months

- ELR in Place of Traditional Resistive Load ROI of 13 months

Ready to learn more about regenerative loads that offer lower capital costs and energy usage? Read the full app note, Regenerative loads: Just how much power can you really save?