Simulate Batteries with the EA Battery Simulator

June 03, 2024 | Topics: Bidirectional Power Supplies

As the demand for reliable and efficient battery technologies grows, so does the need for advanced battery simulation tools to test and simulate those batteries. A battery simulator allows engineers and designers to understand the performance and behavior of a power supply, optimize their designs, and explore the capabilities of a battery cell without extensive physical testing.

Read on and learn how to simulate batteries with our dynamic tool.

Why Battery Simulation Is Important

Battery simulation plays a critical role in the research, design, and development of batteries for:

- Electric vehicles

- Consumer electronics

- A wide range of other devices

Using a battery emulator or simulator allows your team to perform high-precision battery tests and ensure that your designs will effectively meet the demands of your intended use case. In the following, you can further explore the benefits of simulating batteries before implementation.

Advantages of Battery Simulation

By simulating consumer-electronic, automotive, and other types of power sources, your team can attain numerous advantages. Some examples include:

Cost Savings

Under the traditional development process, your team would need to create prototypes of lithium-ion batteries to conduct testing. Each time you discover issues with the battery pack, you’ll have to go back to the drawing board, create yet another prototype, and repeat the testing process.

While you’ll still have to complete a prototyping phase when using cell simulators, you should be able to optimize your design with fewer physical iterations. The end result is reduced development costs and a high-speed project lifecycle that allows you to get to market faster.

Enhanced Testing Accuracy

Simulated test environments provide precise and repeatable conditions that can be difficult to achieve with physical tests. You can run all of your diagnostics processes, including impedance, high voltage, and bidirectional testing, with unmatched accuracy.

Improving the accuracy of your test system can simplify the calibration process and mitigate the amount of variability in the real battery. You can use this information to identify warranty windows for each battery model, ensure constant voltage for the intended use case, choose the proper charger, and enhance the consumer experience.

Improved Design Processes

The best battery simulators have a robust user interface to empower your engineers during the design and testing phases. Your team will be able to quickly iterate on designs, identify potential issues, and optimize performance parameters before physical implementation.

For instance, the EA battery simulator has dynamic analyzer software that carefully tracks everything from the battery charge and internal resistance to the current range and discharge cycle. By providing a comprehensive view of power consumption and the stage of charge throughout each test, our solution gives you actionable insights to optimize the battery design.

Features of the EA Battery Simulator

Our battery simulator test equipment is state-of-the-art. Thanks to its bidirectional DC power supply, our solution can replace a huge range of battery sizes and types. It can output a wide selection of currents and voltages, giving your team precise control over every test.

Since our solution is bidirectional, it can both sink and source power. As such, it’s capable of completely simulating a battery’s operation, including both the charging and discharging phases.

Our high-power system simulates the electrical and chemical characteristics of lithium-ion batteries with capacities ranging from 20Ah to 80 Ah. The versatile tool can also simulate lead-acid batteries with capacities ranging from 35 Ah to 140 Ah. Your team can connect batteries in series or parallel, depending on your testing requirements.

Most importantly, the user-friendly interface makes it easy to customize a full range of testing requirements, including:

- Internal resistance

- State of charge (SOC)

- Capacity

- Ambient temperature

We paired our robust testing hardware with intuitive software that runs on Windows computers. Simply plug in the USB dongle and launch the program to control the power supply while running your tests.

During operation, the simulator will display critical data, including power and output voltage, so your team can easily monitor performance throughout the testing cycle. The software automatically creates a data sheet for review as well.

How to Simulate Batteries With the EA Battery Simulator

Using our battery simulator software is easier than you might expect. Here’s a step-by-step breakdown of the process:

1. Setup and Configuration

Once your EA simulator arrives, carefully unbox it and assemble it according to the provided user manuals. Setup is generally quick and easy, especially if your team has experience with EA equipment or benchtop power supplies. We designed our simulator to ensure a seamless user experience.

Next, check that the simulator is connected to a stable power source. Fluctuations can cause testing inaccuracies, so it’s imperative that the cord be firmly seated in the outlet.

Now, you are ready to plug the simulator into your Windows computer. Simply insert the USB dongle into an open USB port, and the software should automatically run on your computer. If it doesn’t, follow these steps:

- Open the Control Panel

- Click on System and Maintenance

- Open the Device Manager

- Scroll down and select USB to see a list of connected devices

- Click on the EA USB to open the software

Generally, our program will open automatically, and you can skip these steps. However, if it doesn’t, clicking on the USB icon in your Device Manager should cause the application to run.

2. Defining Battery Parameters

At this point, you are ready to define battery testing parameters. Choose the type of battery you wish to simulate (e.g., lithium-ion or lead-acid). Next, enter the specific parameters of your battery, including capacity, voltage, internal resistance, and chemistry.

The setup process is quite easy, and you can save preset testing parameters for later use. After you’ve created a few sets of custom conditions, running future tests will become even more efficient.

When setting your parameters, make sure to create simulation profiles that reflect real-world usage scenarios, including charge/discharge rates, temperature conditions, and load variations. Customize the profiles to simulate specific conditions, such as extreme temperatures or rapid charging cycles.

3. Running Simulations

After you have designated your testing parameters, you are ready to run simulations. Choose the type of simulation you want to run, such as continuous discharge, stress testing, or intermittent load. Generally, you’ll need to perform multiple types of tests to obtain a complete picture of your battery’s performance and durability.

Initiate the simulation process through the software interface. Our software will take it from there, running the complete test based on your chosen criteria. While the test runs, make sure to keep a close eye on fluctuations and note any variances that exceed your predictions.

If you miss something, don’t worry; our software automatically records the simulation data for later analysis. The platform also has export and logging tools to make post-testing evaluation easier. You can forward the results to colleagues, export the data to your preferred software, or create duplicate copies for record-keeping purposes.

4. Analyzing Results

Thanks to our user-friendly solution, you’ll have an abundance of easy-to-digest data for assessing battery performance. Our software automatically converts performance results into charts, graphs, and other visuals. Analyze these records to identify trends and performance indicators.

Focus on critical metrics such as battery capacity retention, efficiency, and thermal performance. Then, continue to make improvements to your design and repeat previous tests until you reach the desired performance thresholds.

Applications of the EA Battery Simulator

EA battery simulators can contribute to numerous industries, including the following:

Automotive

Manufacturers in the automotive sector can use simulators to determine the performance and lifespan of electrical vehicle batteries under different driving conditions. They can also test batteries used in internal combustion engine vehicles.

Consumer Electronics

Designers must stringently test the efficiency and reliability of batteries used in smartphones, laptops, and other portable devices. Engineers often expose these batteries to extreme temperature simulations to verify their safety, as the power cells will frequently be in close proximity to consumers (e.g., in their pockets, on their wrists).

Renewable Energy

Solar and wind system designers may use simulators to evaluate the performance of batteries used to store renewable energy. Comprehensive testing helps promote system efficiency and adequate energy storage.

Best Practices for Battery Simulation

The efficacy of your battery simulations hinges on the quality of your equipment. Once you’ve set yourself up for success with an EA battery simulator, you should take additional steps to promote testing integrity and accuracy. With that in mind, it’s helpful to explore some tips to make your simulations more effective and outline common pitfalls to avoid.

How to Make Your Battery Simulations More Impactful

First and foremost, you need to ensure that all battery specifications and parameters are accurate. Our interface has an easy-to-read heads-up display, so verifying your settings should only take a few seconds. Additionally, it’s important to create realistic scenarios. Don’t design simulation profiles that are too favorable or harsh. Mimic real-world conditions to obtain meaningful results.

Lastly, make sure to regularly calibrate the simulator to ensure its accuracy and reliability. Follow the care and maintenance instructions in our user manual to both maximize your equipment’s lifespan and optimize your simulation’s efficacy.

Common Pitfalls to Avoid

Diligence is key to consistency and accuracy during testing. You’ll also need to be mindful of common pitfalls, the most concerning of which is inaccurate data entry. Double-check all inputs to avoid errors that could skew your simulation results. Even a seemingly small input error can lead to drastic discrepancies on the back end.

Another common mistake involves ignoring environmental factors. You must consider the impact of environmental conditions like temperature and humidity. These variables can have a huge effect on battery performance, so you need to include them in your tests.

The third mistake involves becoming hyper-focused on one data point or metric. You should always conduct a thorough analysis of simulation data to draw actionable insights and improve your design. Don’t just review the variable that you were testing — look at the totality of the data.

Unlock the Benefits of an EA Battery Simulator

An EA battery simulator offers a wide range of benefits, including reduced costs, accelerated project timelines, and better performance. By leveraging one of our simulators and adopting established testing best practices, you can create better products and elevate the end user’s experience.

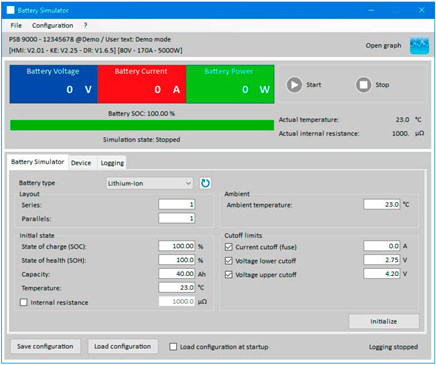

The upper part of the screen shows the actual voltage, current, and power output values. The software will read these values from the power supply, even if the simulation is not running. One reason for this is that even when the DC output is off, there may be a voltage on these terminals that comes from an external source. Also present on this part of the screen are manual start and stop controls, the simulated state of charge, the actual ambient temperature, and the actual internal resistance.

Below this are three tabs: Battery Simulator, Device, and Logging. Clicking on the Battery Simulator tab allows the user to set up simulation parameters, including:

- Battery type. This menu lets users select either Lead-Acid or Lithium-Ion. The battery type selected will set the range for the Capacity, Internal resistance, Voltage lower cutoff and Voltage upper cutoff parameters.

- Layout. This parameter lets users specify the number of batteries that they wish to simulate, and how those batteries are connected. So, for example, to simulate a lithium-ion battery pack with an output of 420 V, users would specify 100 lithium-ion cells in parallel. Note that to perform this simulation correctly, a power supply that can provide or sink a voltage of at least 420 is necessary.

- Initial state. The settings in this section allow users to specify the initial state of the simulated battery, including:

- State of charge (SOC). To simulate a fully charged battery, set this parameter to 100%; set to 0% to simulate a fully discharged battery. A “discharged” lithium-ion battery will have an output voltage of approximately 2.5 V, while a discharged 12 V lead-acid will be about 10.5 V.

- Capacity. For lead-acid batteries, the range for this parameter 35–140 Ah. For lithium-ion batteries, the range is 20–80 Ah.

- Temperature. This setting defines the initial temperature of the battery body. The range is -10–45 °C (14–113°F). Typically, users set this temperature to be the same as the ambient temperature.

- Internal resistance. If users check this box, the values for SOC and Temperature will be reset and no longer settable. The reason for this is that the initial internal resistance is only valid for an SOC setting of 100% and a battery temperature of 23°C (73.4°F). The value for this parameter can be set to between 3000 and 6000 μΩ for lead-acid batteries and 1000 and 2000 μΩ for lithium-ion batteries.

- State of health (SOH). This parameter specifies how much of a battery’s capacity is truly available. An SOH of 100% represents a brand new battery

Do you want to see our equipment in action? Schedule an online demo today. You can also request a quote and place your order, all from our user-friendly website.