This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful. See our privacy policy.

Suppose your responsibility is testing electric vehicle (EV) batteries. In that case, you are contending with increasing production volumes to address market growth and higher kilowatt-hour capacity battery packs to extend driving distance. You also must have test capability for testing higher voltage battery packs, enabling vehicles to use smaller gauge wiring for weight reduction.

Suppose you also must test battery packs for off-road vehicles. In that case, you have the added challenge of verifying that battery packs can safely withstand the additional mechanical stresses due to operation on rough terrain and exposure to heavy loads.

Battery test systems need to accommodate battery voltages evolving from 400 V to 800 V and higher. In addition, battery capacities are increasing to over 100 kWh. Furthermore, off-road battery packs require vibration and shock testing. EA Elektro-Automatik (EA) has the DC programmable power solutions for all these requirements. We will recommend test requirements and introduce test instruments and systems to address all the challenges of off-road EV battery pack testing.

Recommended tests for off-road EV battery testing

Determining that batteries meet their specifications for deployment in off-road vehicles includes tests that all EV battery packs should pass and some tests specific to off-road vehicles. These tests are:

- DC internal resistance – A measurement of internal resistance assesses the battery’s state-of-health (SOH) and capacity to deliver a load current at a specific voltage.

- Insulation resistance – A lower than the specified Insulation resistance, determined from a leakage current measurement, results in reduced battery efficiency and can compromise safety.

- Pulse testing – Generating high current, short duration pulse loads determines how well the battery can dissipate heat during high power demand and absorption conditions. Pulse tests simulate rapid acceleration and regenerative braking conditions. This stress test evaluates the state-of-charge (SoC) indicative of drive distance or usage time between charges.

- Drive cycle simulation – Varying the load profile according to standard drive simulation tests, such as Federal Test Procedure, FTP-75, provides a standard for comparison of battery performance and vehicle driving distance.

- Battery cycling – Conducting charge and discharge cycles tests the battery’s voltage-time discharge characteristic and charge time. The data yields an estimate of the number of charge/discharge cycles before battery capacity is significantly degraded.

- Vibration and shock testing – These are the tests that qualify a battery pack for use in off-road vehicles. Subjecting the battery pack to various vibration modes and intensities will reveal mechanical weaknesses among cell connections and in the battery pack assembly. In addition, a drop test will simulate the shock a battery pack in an off-road vehicle will encounter. Both battery testing methods are quality control tests performed on a statistically significant number of battery packs.

Can your DC programmable power supplies handle off-road battery testing?

Can your DC programmable power supplies handle off-road battery testing?

EA Elektro-Automatik instrumentation for EV battery testing

EA offers lab-to-field solutions for battery testing, ranging from individual DC programmable power instruments for R&D and quality control and complete turnkey systems for production testing. EA addresses the challenges of battery testing with three solutions:

- EA-PSB Bidirectional Power Supplies

- EA-BT 20000 Triple Battery Tester

- EA-BTS 10300 Battery Cycler and Test System

PSB bidirectional power supplies

Our line of PSB bidirectional power supplies can both source and absorb power to combine the functions of a power supply and a load in one instrument. PSB power supplies are high power density instruments that can deliver or absorb up to 30 kW. Models can have voltages up to 2000 V and current of as much as 1000 A to test battery cells and a wide range of EV battery packs.

EA-PSB power supplies have an autoranging output characteristic, allowing delivery (or absorption) of maximum power from the maximum rated output voltage down to 1/3 of the rated output voltage. A conventional supply with a rectangular output characteristic can only deliver full power at its rated voltage. To deliver the equivalent amount of current as an EA-PSB supply, the conventional power supply would need to have three times the power of the EA-PSB supply. Thus, EA-PSB supplies can deliver more power in less space and at a lower cost than conventional power supplies.

EA-PSB power supplies also have a built-in arbitrary waveform generator that can apply a load profile to simulate driving and usage conditions. With a 500 µs slew rate, PSB supplies can generate narrow current pulses for battery pack pulse testing.

Testing EV battery packs consumes a substantial amount of energy. EA-PSB power supplies can return power to the AC grid with an industry-high 96.5% efficiency. The use of these regenerative power supplies can provide significant annual utility savings.

EA-PSB bidirectional power supplies provide more performance, more power, and higher efficiency in less space with greater cost savings. Integrating a load and an arbitrary waveform generator combines the functionality of three instruments into a single physical instrument. The EA-PSB power supply is a superior battery test instrument.

EA-BT 20000 battery tester

The EA-BT 20000 can test up to three battery cells or three battery packs simultaneously. Models can have 30 kW that support power up to 10 kW/channel with voltage up to 920 V or current up to 600 A/channel. The EA-BT 20000 performs testing, battery simulation, and battery cycling. In addition, this instrument includes:

- An active pre-charge control to prevent unwanted inrush current that could damage the battery and the contactor controlling power to the battery

- Cable overload warning and cable overload protection to test for broken cables, poor cable connections, or a reverse polarity condition

- Zero current turn-off to maximize DC contactor life

The EA-BT 20000 battery tester is available in a triple output model.

The EA-BT 20000 battery tester is available in a triple output model.

EA-BTS 10300 Battery Cycler and Test System

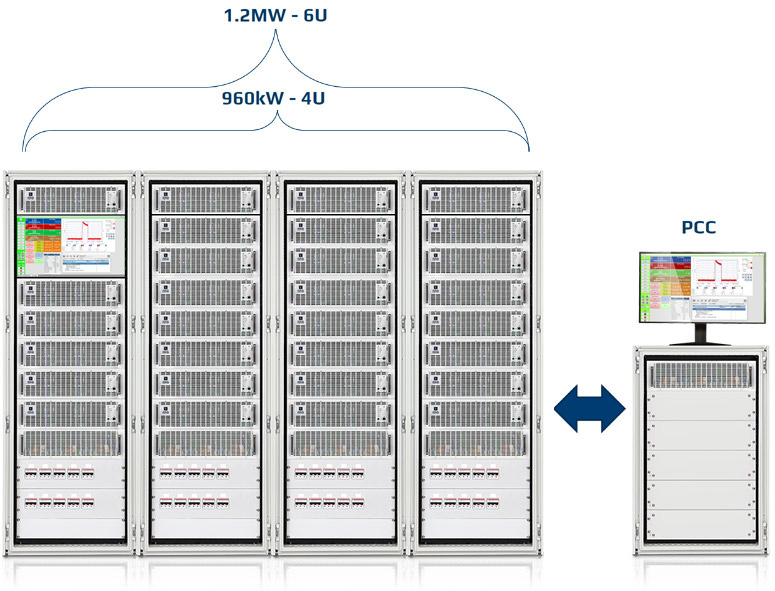

For a complete turnkey battery test system that includes temperature cycling, we have the EA-BTS 10300. This system provides as much as 300 kW in a 19-inch wide test rack. Maximum voltage is 2000 V or maximum current can be 2400 A/rack. The racks can be paralleled to have a total capacity of 3.84 MW. The EA-BTS 10300 provides:

- The most power in the least amount of space, 30 kW in only 6.5 sq/ft

- The greatest cost savings with the highest regenerative efficiency of greater than 96.5%

- Maximized uptime with a modular system that allows power instrument exchange in under 30 minutes

- Fastest data acquisition rate of 1.5 kHz

- Widget-based software to customize display to user-required parameters

The high voltage and high current capacity of a test rack combined with the ability to easily add test racks ensures that the EA-BTS 10300 can meet current and future test requirements.

The EA-BTS 10300 is a high-density, compact, integrated battery tester that can be upgraded in future applications.

Solutions for any EV battery testing application

Whether you need a test system for R&D, a system for quality control, or a complete high-volume production system, EA can serve your requirements. You can design your own system based on EA-PSB bidirectional power supplies or EA-BT 20000 Triple Battery Testers. Alternatively, you can meet current and future production needs with the EA-BTS 10300 Battery Cycler and Test System. All these options allow for the interface and control of a vibration station. The EA-BTS 10300 system can expand to test new, higher-capacity batteries and more batteries for higher demand requirements. With the ability to control a vibration station, EA solutions can address the challenges of ensuring robust, reliable batteries for off-road EVs.

Learn more at www.eapowered.com or contact us at sales@elektroautomatik.com