This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful. See our privacy policy.

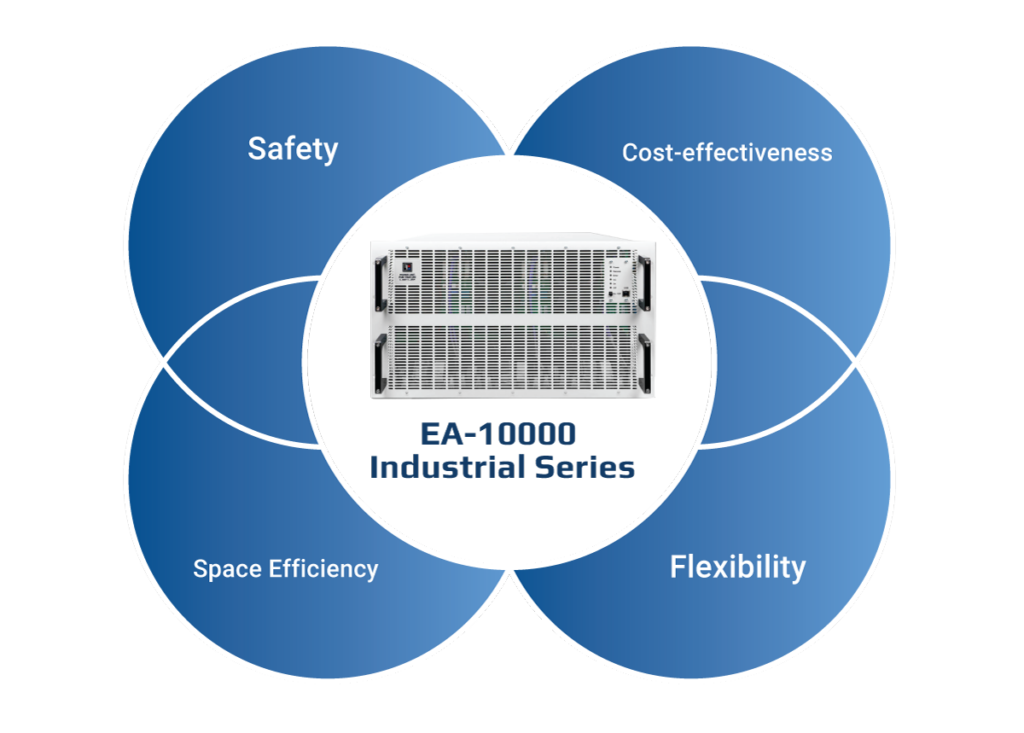

In the realm of high-power systems, where innovation drives progress, transitioning from design to manufacturing is a critical challenge for test engineers. The complexity of applications, such as renewable energy systems, electric vehicles, battery storage, and advanced avionics, demands a careful balance in achieving flexibility, safety, cost-effectiveness, space efficiency, and energy conservation.

The EA 10000 Industrial Series: A game-changing solution

EA Elektro-Automatik introduces a groundbreaking solution that addresses these challenges seamlessly—the EA-10000 Industrial Series. Comprising 21 models of 60 kW instruments and 29 models of 30 kW instruments, this high-power series includes conventional DC programmable power supplies, bidirectional power supplies and regenerative electronic loads.

Where choosing one feature meant sacrificing another, now design and test engineers can have it all.

Where choosing one feature meant sacrificing another, now design and test engineers can have it all.Let’s delve into how this series reshapes the landscape of high-power testing.

Power packed: unmatched power density

At the core of the EA-10000 Industrial Series is its unparalleled power density. With 60 kW housed in a single 6U high, full rack-width enclosure and 30 kW in a 4U enclosure. Leveraging SiC technology, these instruments stand as a testament to innovation. Now, test engineers have a single instrument capable of meeting power requirements ranging from 30 kW to 60 kW.

Ready to Get Started? Request a Quote

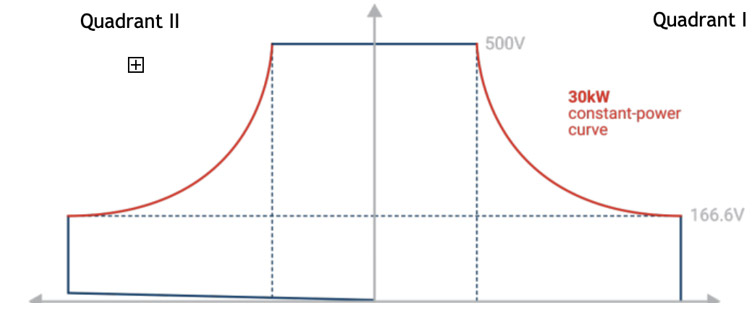

Here is another advantage the Industrial Series has that also cuts down on the number of DC programmable power equipment test engineers need: TRUE autoranging.

The TRUE autoranging output characteristic distinguishes EA’s instruments from conventional ones, allowing for a wider voltage and current range. This flexibility ensures that the test engineer can adapt to the current product’s requirements while accommodating future versions seamlessly.

TRUE Autoranging provides more testing capability in one instrument.

TRUE Autoranging provides more testing capability in one instrument.Safety reinvented: Expanded capacity and protective functions

In high-power systems, safety takes precedence. The EA-10000 series can connect up to 11 test racks, creating a system with a staggering 3.84 MW of capacity. The Share-Bus feature ensures that each instrument shares an equal portion of the total load, preventing dangerous overloads and contributing to a safe and simplified high-power connection.

Each instrument in the series incorporates four protective functions—overvoltage, overcurrent, overpower, and overtemperature protection—to further enhance the safety of test systems. Alarms triggered by any of these conditions prompt an immediate shutdown, preventing further complications.

Watch the EA-10000 Industrial intro video here for more benefits and features:

Bidirectional power supply efficiency redefined: Energy savings and environmental impact

Efficiency is a cornerstone of the EA-10000 Industrial Series. Regenerative bidirectional power supplies and electronic loads boast up to 96.5% efficiency, effectively absorbing and returning energy to the power line. In practical terms, this translates to substantial energy savings—up to 43,425 kWh annually compared to resistive bidirectional counterparts. The regenerative capabilities not only save on utility costs but also reduce cooling infrastructure expenses, making them an environmentally conscious choice.

On the AC input side, active power factor correction enhances efficiency even at low power delivery, contributing to lower internal temperatures and increased component durability. This efficiency extends the lifespan of instruments, particularly the regenerative bidirectional power supplies and electronic loads.

Calculate your ROI from using a regenerative power supply. Try our ROI calculator here.

Calculate your ROI from using a regenerative power supply. Try our ROI calculator here.Compact yet comprehensive: Space efficiency and flexibility

The high-power density of the EA-10000 Industrial Series enables the accommodation of 360 kW capacity in a single standard 42U high rack, occupying a mere 0.6 m² (6.5 sq ft) of floor space. This compact design results in significant annual savings in test overhead costs and reflects the series’ commitment to minimizing manufacturing floor space.

Flexibility is another hallmark of the series, with instruments seamlessly interfacing with both personal computers (PCs) and programmable logic controllers (PLCs).

Supporting various command languages and interfaces, including USB, Ethernet, CAN, CANopen, RS-232, Profibus, EtherCAT, Profinet, ModBus, and multiport Ethernet, the 10000 series offers unparalleled automation capabilities without the need for additional external interface adapter hardware.

Conclusion: no compromises, only advancements in DC programmable power supplies

In conclusion, the EA-10000 Industrial Series from EA Elektro-Automatik emerges as a comprehensive and revolutionary solution for high-power testing. Meeting all the objectives of test engineers, from power capacity and safety to efficiency and flexibility, this series sets a new standard in the industry. By eliminating tradeoffs, EA Elektro-Automatik empowers design engineers to navigate the complex landscape of high-power applications easily.

For further insights into the transformative capabilities of the EA-10000 Industrial Series, explore the EA-10000 Industrial Series or connect with an Application Engineer. Elevate your high-power testing experience with the future-ready solutions of EA Elektro-Automatik.

Read the full App Note for full features of the EA-10000 Industrial Series

Read the full App Note for full features of the EA-10000 Industrial Series