Safeguarding DC Programmable Power Supplies: Protecting Against Inductive, Capacitive and Oscillatory Loads

August 25, 2023 | Topics: Bidirectional Power Supplies, Electronic Loads, Power Supplies

Connecting a DC power supply to a load may seem clear-cut, but it can become challenging in certain situations. While power supply manufacturers design their products to be stable when powering various loads, certain load characteristics can pose risks and even damage the power supply’s output stage. Inductive and capacitive loads and loads with rapid changes in load current can create conditions that lead to oscillation, jeopardizing both the power supply and the load. In addition, inductive and capcitive loads can apply energy to the power supply. In this blog, we will explore the different types of hazardous loads for DC power supplies and offer solutions to ensure reliable power supply operation and load protection.

Ready to Get Started? Request a Quote

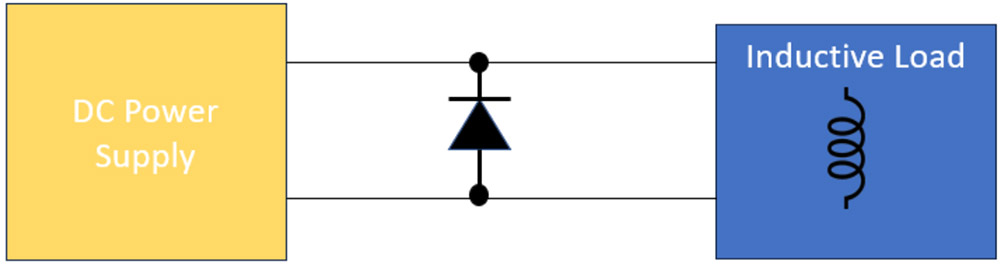

- Inductive loads:

Inductive loads, such as motors, solenoids, and electromechanical relays, can be an energy source that feeds into a power supply and damages it. When voltage and current are applied to an inductive load, a magnetic field builds up, storing potential energy. The magnetic field collapses when the power is removed, inducing a voltage spike in the opposite polarity. This back electromotive force (EMF) can damage the power supply’s output stage.

To protect the power supply, a reverse bias diode, known as a flyback diode or a freewheeling diode, is added across the power supply’s output. This diode allows the current generated by the inductive load to flow through it when the power supply turns off, protecting the power supply from the back EMF.

Figure 1. Use of a flyback diode to protect the power supply from back EMF.

Figure 1. Use of a flyback diode to protect the power supply from back EMF. - Capacitive loads:

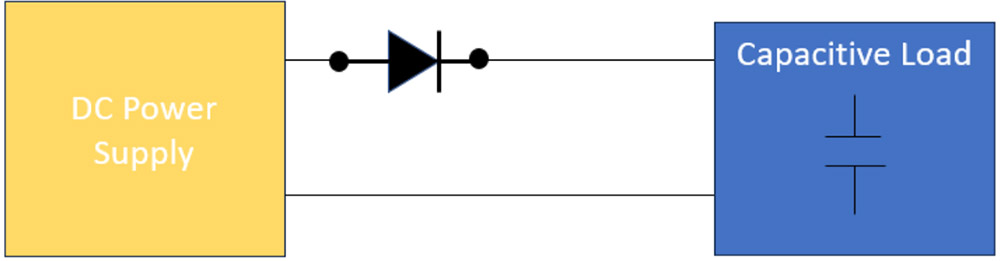

Capacitive loads, like supercapacitors, capacitor load banks, or filters, can generate hazardous voltage spikes to a power supply. Similar to inductive loads, capacitive loads store potential energy. When the power supply voltage falls below the voltage on the load, the load delivers a current surge that can damage the power supply.

A series diode is added to the output to prevent reverse currents from capacitive loads flowing into the power supply for protection. This diode is forward-biased when the power supply energizes the load but becomes back-biased when the power supply voltage drops below the load voltage.

Figure 2. A series diode protects the power supply from capacitive load discharge.

Figure 2. A series diode protects the power supply from capacitive load discharge. - Battery loads:

As electrochemical power sources, batteries can damage a DC programmable power supply if the voltage exceeds the power supply voltage. Like capacitive loads, a series diode can protect the power supply from the battery discharge current.

On the other hand, the DC programmable power supply can also damage the battery if a reverse polarity connection occurs. A polarity detection circuit and a contactor are used for safe battery test systems to prevent applying power to an incorrectly connected battery.

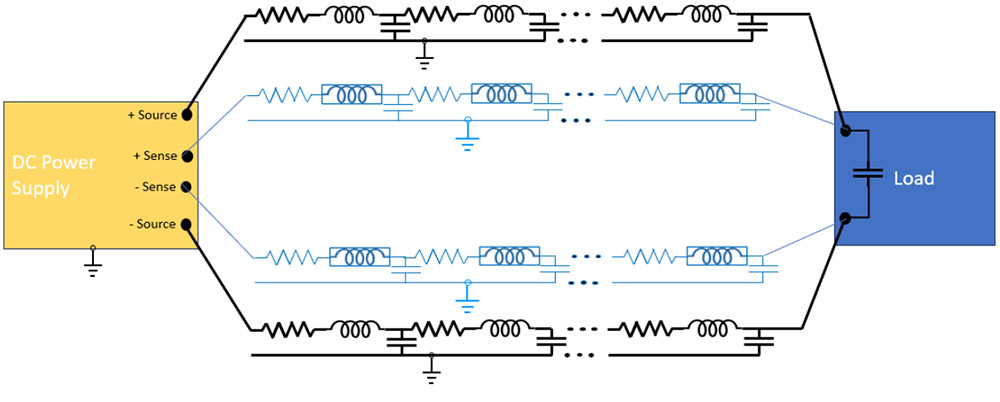

- Oscillation in power supply-load circuit:

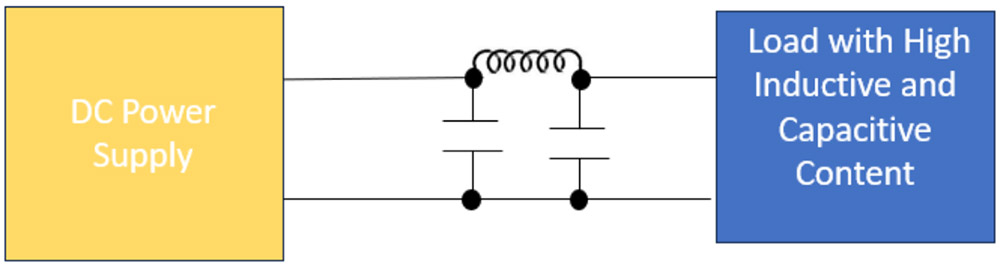

Certain types of loads can cause the power supply to oscillate, potentially damaging both the power supply and the load. Highly capacitive loads, inductive loads, and loads with fast-changing characteristics can lead to instability. Implementing filters, such as Pi-filters, can mitigate the effects of highly reactive and rapidly changing loads.

Additionally, proper grounding techniques are essential to prevent noisy ground currents from flowing into the power supply wiring, which can cause instability. Shortening the wiring between the power supply and load and using shielded wiring can also reduce the chances of picking up noise from external sources.

Figure 3. (Top figure) A Pi filter can isolate the power supply from high-frequency effects.

Figure 3. (Top figure) A Pi filter can isolate the power supply from high-frequency effects.

Bi-directional DC power supply:

An alternative solution to using external components for protection is to consider a bi-directional DC power supply. This power supply can safely absorb and deliver power, making it suitable for capacitive, inductive, and active loads. Bi-directional power supplies are cost-effective when a DC test circuit requires both source and load functionalities at different times during a test protocol.

An illustration of a bi-directional DC power supply is the EA Elektro-Automatik PSB 10000, equipped with an integrated, regenerative electronic load and true autoranging capabilities. This advanced power supply ensures that the device’s whole source and sink power is accessible across a broad operating range. With its regenerative electronic load feature, the PSB 10000 can safely absorb and efficiently return power to the grid, making it highly versatile and suitable for various applications.

Conclusion

Connecting a DC power supply to a load requires careful consideration of the load characteristics to ensure reliable power supply operation and load protection. Inductive and capacitive loads can cause damage to the power supply, while oscillation in the power supply-load circuit can be detrimental to both the power supply and the load.

We can create a stable and safe power supply-load circuit by understanding the load characteristics and implementing appropriate protection measures, such as adding reverse bias diodes and employing proper grounding techniques. Additionally, bi-directional power supplies offer a versatile solution for applications that require both source and load functionality. By following these recommendations, we can ensure the efficient and secure operation of DC power supplies and safeguard against potential hazards in various load scenarios.

For more challenges and solutions in safeguarding DC power supplies, read the white paper Ensure Protected Reliable Operation for a DC Power Supply in Any Load Circuit.