How Programmable DC Power Supplies Work: A Comprehensive Guide

January 26, 2023 | Topics: Power Supplies

Direct current (DC) is a unidirectional electric current, which means the flow of charge always occurs in the same direction. Conversely, alternating current (AC) changes the direction of charge flow, creating a periodic back-and-forth motion. AC current is easier to generate and more efficient. It also represents the type of electric current produced by the majority of power plants.

Direct current power supplies are a staple in several fields, from research and development to manufacturing and consumer applications. These devices convert alternating current from wall outlets into DC, offering power to a wide array of electronic devices and systems.

Under ideal conditions, a direct current power source provides steady DC voltage, regardless of load current. However, no electronic product provides constant voltage under all conditions and circumstances. Instead, output voltage exhibits fluctuations, as do current flows.

The key to effective power supply design is understanding how to use DC power supply solutions in real-world settings. On that note, join us as we explore questions like “What is a DC power supply?” and “How does a DC power supply work?” We’ll also examine programmable solutions such as autoranging DC power supplies and their impact on maintaining consistent voltage levels.

What Is a DC Power Supply?

A DC power supply is an electronic device that converts electrical energy from one form to another, specifically from alternating current into a stable and controlled direct current output. Phone chargers, AC to DC adapters, and other battery-powered device power supplies (e.g., laptops, rechargeable vacuums) are a few common examples of DC supply systems.

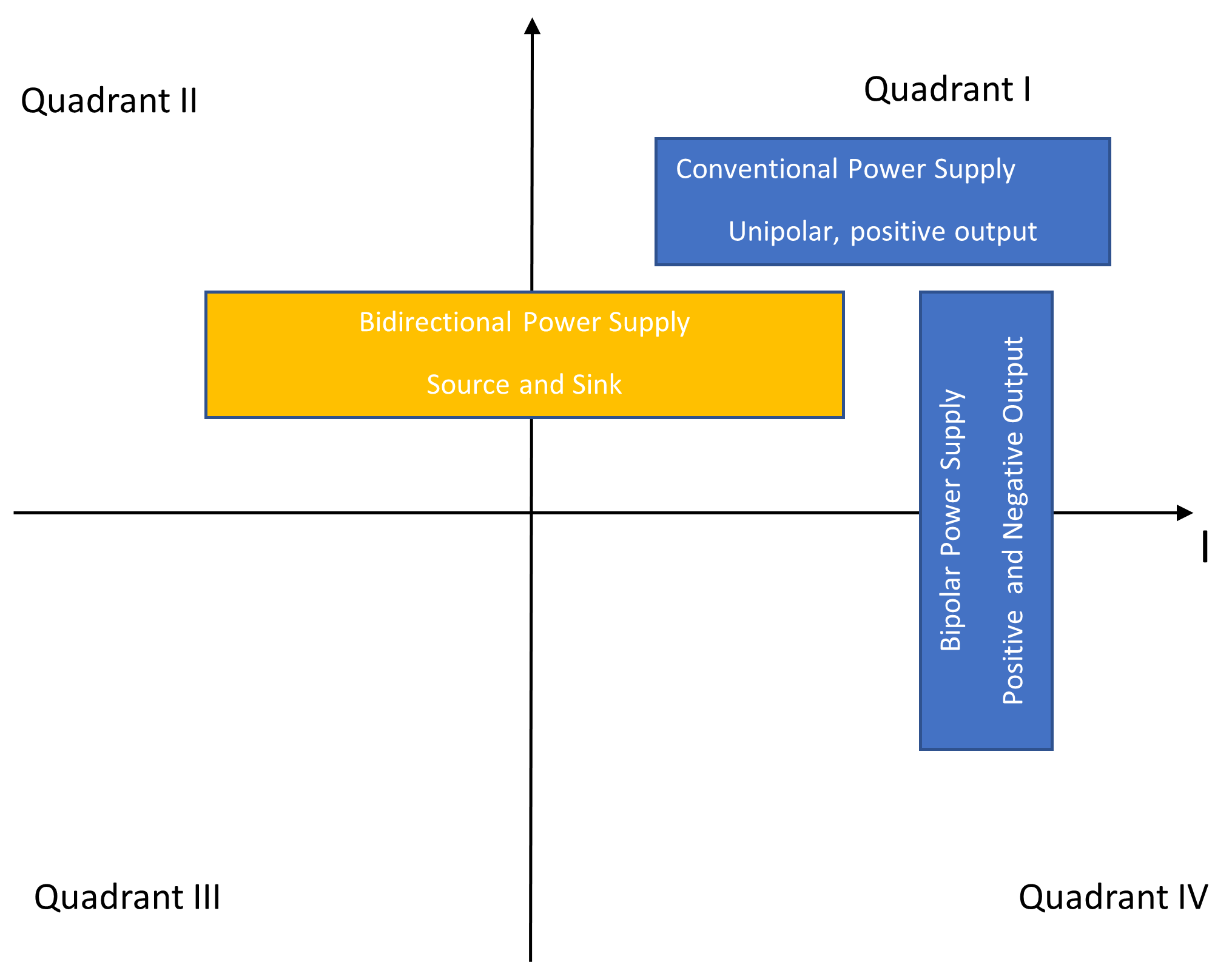

DC power supplies can be grouped into one of two broad categories: uni-directional and Bidirectional. A uni-directional system only converts one kind of electrical power into one other type. In this case, they convert AC power to DC power.

A Bidirectional Bidirectional is capable of switching power supplies. In other words, it can take AC power and turn it into DC or vice versa.

How Does a DC Power Supply Work?

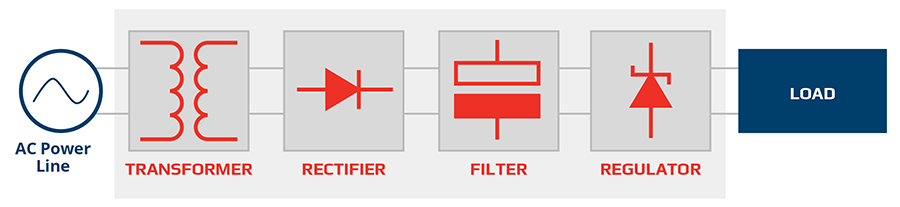

A DC power supply operates by first rectifying the incoming AC power to DC power if starting from an AC source. This process involves the conversion of AC voltage to DC voltage, typically using diode rectification. After the rectifier completes this process, the DC power might still contain fluctuations or ripples, which are smoothed using filtering stages to produce a more stable DC output.

Finally, a regulation stage adjusts the output to maintain a constant voltage or current level despite variations in load or input voltage. This can be achieved through linear regulation, which dissipates excess power as heat. It can also be achieved more efficiently through switching regulation, which uses high-frequency switching techniques to control the energy delivered to the load.

Figure 1. Generic block diagram of DC power supply

Figure 1. Generic block diagram of DC power supplyDeviation From Ideal Output

DC power supply outputs don’t always deliver the precise output programmed by the user. The manufacturer will define an accuracy range for DC output, which is expressed as output or display accuracy. Several factors can contribute to deviations from ideal output, including the following:

Temperature

Environmental temperatures have a major impact on both AC/DC power supplies. When the external temperature drops below the temperature range that the manufacturer calibrated the supply for, voltage output can decrease.

Therefore, you must understand the intended operating temperature of your equipment. This is especially important in high-stakes industrial applications where unexpected downtime or performance degradation can negatively impact profitability.

High Current Loads

When current loads are high, more voltage drops due to the internal resistances of different components, including the inverter, inductor, circuitry, transistor, and capacitor. That’s why you must familiarize yourself with how many volts your equipment is rated for and stay away from the upper ends of that threshold.

In response to these factors, many systems designers use autoranging power supplies, which are designed to accommodate the natural variation in currents. With traditional systems, power supplies only offer maximum power output at full-scale voltage. This means that they can only produce output that is consistent with a specified value.

Conversely, autoranging solutions have a voltage range. These programmable DC sources maintain full power across a broader mix of output voltages and currents. As such, they can accommodate different voltages and provide better stability and performance.

Understanding Power Supply Topologies

Generally speaking, there are two types of power supply topologies: linear or switching. Each topology has its own method of operation and unique characteristics.

Linear Power Supply

A linear power supply is like a constant, steady stream of water from a reservoir to your house, where the reservoir’s level (voltage) is much higher than what you need at your tap. To get the right amount of water flowing at your tap, you use a valve (regulator) to reduce the flow to a usable level.

The linear method provides a very clean and stable flow without much noise variation. However, it’s not very efficient because a lot of energy is wasted in the process of reducing the flow to the right level, primarily getting lost as heat. As a result, it is best suited for lower-voltage applications

Switching Power Supply

On the other hand, a switching power supply works more like a pump system that turns on and off rapidly, filling a tank at your house to the optimal level. It only pumps the amount of water (energy) you need, making it much more efficient than letting excess water flow and go to waste.

The rapid on-and-off operation (switching) allows it to adjust to the energy needs efficiently, with less energy wasted as heat. This results in efficiencies in the 90% range. Comparatively, efficiencies for linear power supplies are under 50%.

The downside to switching is that it is much noisier. It’s also more complex to build and manage these systems. Despite the complexity and noise, its efficiency, smaller size, and lighter weight make it preferred for applications needing a lot of power.

Different Versions of DC Power Supplies

There are several variations of DC power supply solutions, including:

Benchtop

A benchtop DC power supply is designed for lab and educational settings. As the name suggests, it is often used on workbenches and offers a range of outputs that can be adjusted manually using a digital interface or control knob. Some models may include advanced features like programmable sequences or remote control options.

The main advantage of benchtop power supplies is their versatility and ease of use, making them ideal for experiments, testing, and prototyping. They also provide precise control over output parameters, and their robust design can handle varied usage.

Modular

Modular power supplies consist of a frame or chassis that’s able to house multiple power supply modules. Each module can have different characteristics, and users have the ability to configure or expand the system by adding or changing modules.

Flexibility is a significant advantage of modular systems. They can be customized to meet specific needs, making them suitable for complex applications where requirements might change over time. They also save space and can be more cost-effective than having multiple separate power supplies.

Programmable

Programmable power supplies allow you to set and control output parameters through software, either on the device itself or via a computer interface. They can store multiple profiles for different tests or devices and may include features like time-dependent sequences, constant current or voltage modes, and remote sensing.

The main benefit, though, is their ability to automate tests and procedures, which can add value to your production testing workflows while promoting better quality assurance. Programmable supplies offer high efficiency and the flexibility to adapt to a range of tasks without manual intervention.

Other Types

Besides these, there are specialized types of DC power supplies like high voltage, low noise, or application-specific supplies designed for particular industries or devices. Each type caters to specific needs, offering a blend of features, efficiency, and control to match the demands of different users and applications.

Figure 2. Three types of DC power supplies

Figure 2. Three types of DC power suppliesControlling the DC Output

Controlling the DC output of power supplies involves adjusting and stabilizing the voltage, current, and sometimes other parameters, like power or resistance, to meet the specific needs of a device or application. There are several methods for controlling DC output, including:

Manual

Analog systems and basic power supplies typically have dials or knobs, allowing you to manually adjust output voltage or current. While straightforward, this method requires you to carefully set and monitor the values.

Digital

More advanced power supplies provide digital interfaces with buttons or touchscreens, enabling you to set precise output parameters. Digital control systems typically offer the ability to store and recall settings, making repetitive tasks easier.

Programmable

Programmable power supplies are power sources controlled digitally, delivering precise and customizable voltage, current, and frequency levels tailored to meet specific power and control requirements.

Feedback Loops

Many power supplies use feedback loops to maintain stable outputs and minimize the risk of power loss. Sensors monitor the output parameters and feed this information back to the control system, which adjusts the power supply to maintain set values.

Regardless of which solution you choose, you must maintain precise control over DC outputs. Doing so allows you to:

- Protect components

- Ensure performance

- Promote energy efficiency

- Enhance safety

With that in mind, you should implement an output control mechanism consistent with your skill level and the complexity of your intended use case.

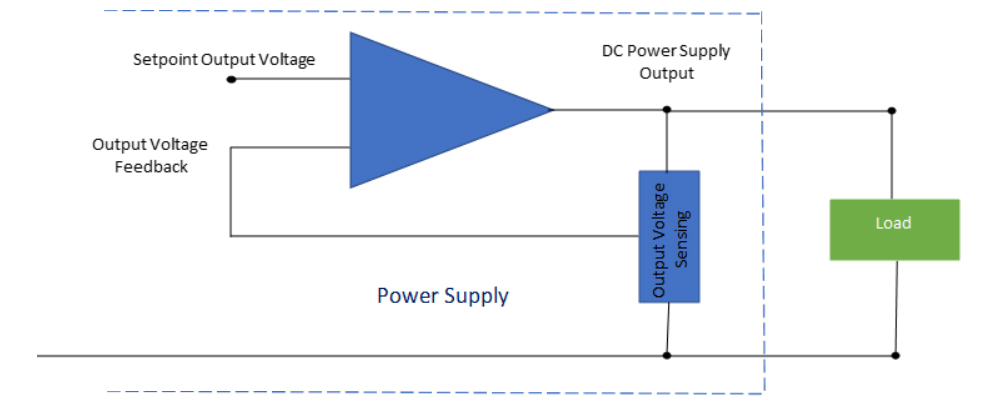

Figure 3. Power supply output stage showing voltage control (not showing output filtering)

Figure 3. Power supply output stage showing voltage control (not showing output filtering)Monitoring the voltage at the DC power supply output terminals is sufficient when the load draws a small amount of current. The voltage drop across the lead wires is insignificant at small load currents. However, with large load currents, the voltage drop across the lead wires can be substantial, and, the voltage applied to the load is lower than the programmed output voltage:

VLoad = VSupply – 2·VLead

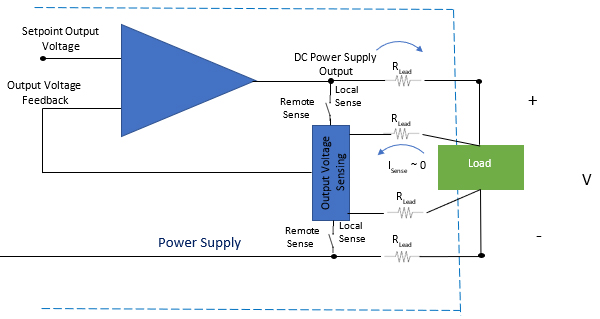

We can correct for the lower voltage at the load if the DC supply is designed with 4-wire connections in which two wires supply power to the load and two wires sense the load voltage. Figure 4 shows a 4-wire connection to a load.

Figure 4. Output stage showing local and remote sensing

Figure 4. Output stage showing local and remote sensingThe Output Voltage Sensing circuit has a high input impedance, so the current drawn by this circuit is extremely small. With negligible voltage drop in the sense wires, the voltage sense circuit measures the actual voltage at the load and feeds that voltage back to the power supply’s power amplifier. The amplifier raises its output voltage by 2·VLead to compensate for the voltage drop in the leads. This feature is known as remote sensing and ensures the output at the load is the desired voltage. When not using a 4-wire setup, the regulator uses local sensing, which maintains the output voltage at the voltage on the output terminals. Using a 4-wire connection ensures greater accuracy of the voltage at the load.

Exploring Output Characteristic Options

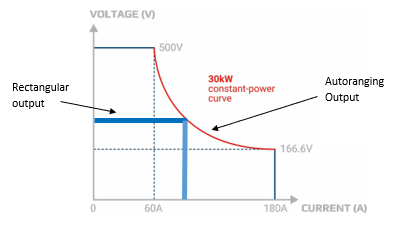

Power supplies deliver DC energy using different methods. One of the most common approaches is the I-V characteristic, which is rectangular. You can set the supply’s output to any combination of current and voltage values that lie within the maximum rated current and voltage rectangle. However, it will only provide full power at the maximum voltage and maximum current setpoint

A second and more sophisticated method is known as autoranging. Systems with autoranging capabilities use a combination of hyperbolic and rectangular output. As a result, the system can supply a wider range of output voltage and load current, while still providing full power.

Through autoranging, you can deliver a full power output in more circumstances, achieve greater flexibility, and unlock cost savings.

Figure 5. Comparison of a rectangular output characteristic with an autoranging output characteristic

Figure 5. Comparison of a rectangular output characteristic with an autoranging output characteristicEnhancements of Power Supply Performance

To make power supplies more versatile and efficient, you can implement them with advanced features. Two examples include waveform generation and multiple control interfaces. Waveform generation is the process of creating electrical waves in different shapes to accommodate specific use cases.

Many power supplies are equipped with digital and analog interfaces. This means you can easily connect them to computers, automated control systems like Programmable Logic Controllers (PLCs), and other electronic instruments.

Bidirectional power supplies are particularly useful enhancements, as they can absorb energy back to the AC power grid and achieve up to 96% efficiency. These solutions are known as regenerative instruments. The downside of regenerative instruments, PLCs, and waveform systems is that implementing them requires more complex designs.

Applications of Programmable DC Power Supplies

Every industry that incorporates electronics into its products relies on direct current power supplies. Design engineers leverage DC supplies to develop new products and circuitry. On the testing side, engineers use DC power supplies to ensure the performance of manufactured products before they are made available to consumers.

Additionally, design and test engineering teams often simulate products using programmable direct current power supplies. Some of the items they simulate include batteries, fuel cells, and solar panels. Bidirectional units act as a source to simulate a battery charger or battery. They can also use the supply to simulate a discharged battery or the circuit that a solar cell will power.

These are just a few examples of the versatility and usefulness of programmable direct current power supplies.

Empowering Your Projects With Programmable DC Power Supplies

Selecting the right programmable DC power supply can significantly impact the success of your projects. By understanding your options, you can choose a solution that best fits your needs.