Repurposing and Recycling EV Batteries

July 06, 2021 | Topics: Autoranging, Battery Test, Bidirectional Power Supplies, Electronic Loads

It’s no secret that there are more electric vehicles (EVs) on the road today than ever. Since 2015, the number of electric vehicles worldwide has grown from 1.4 million to more than 8 million today. Because EVs emit far fewer hydrocarbons than vehicles powered by internal combustion engines, they are an important part of the plan to combat climate change.

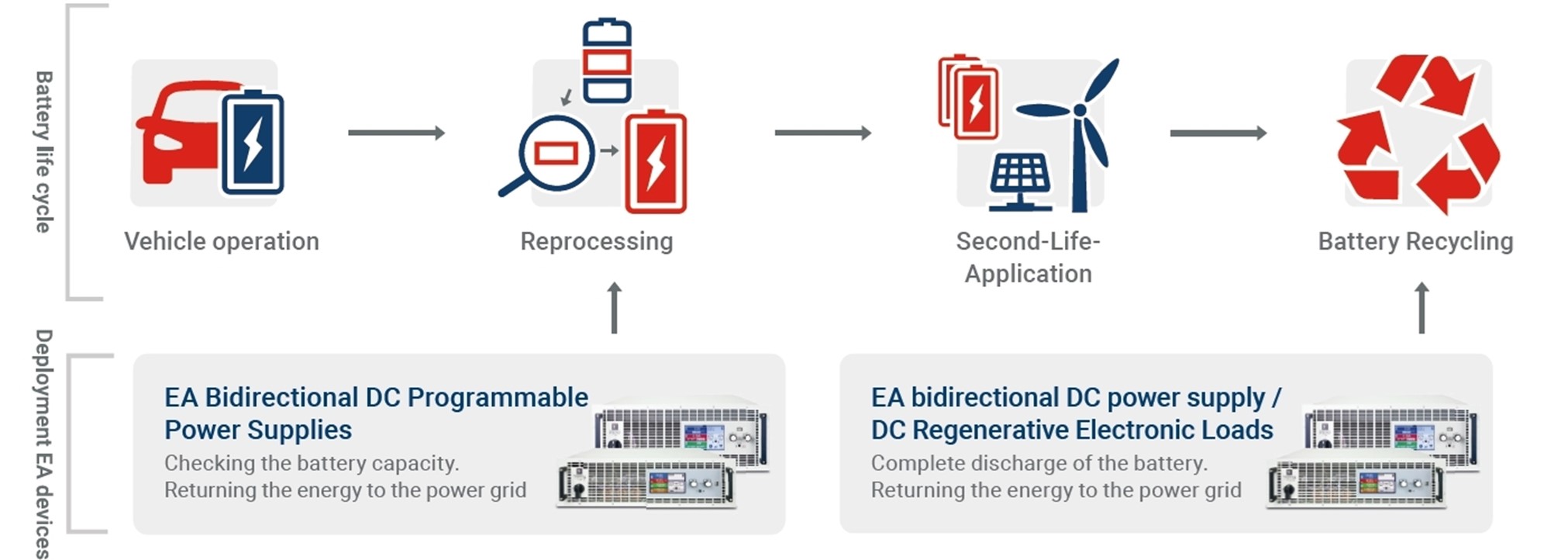

EVs do, however, present other challenges. As they become more widely used, there is a question of how best to re-use or recycle the lithium-ion batteries that power these vehicles. Fortunately, Elektro-Automatik power supplies and electronic loads—including the EA-PSB 10000 bidirectional power supply and the EA-ELR 10000 regenerative electronic load—make this job easier.

Ready to Get Started? Request a Quote

The EA-PSB 10000 bidirectional power supply is ideal for testing the suitability of used EV batteries for a second-life application, while the EA-PSB 10000 and the EA-ELR 10000 electronic load allow recyclers to discharge batteries fully for recycling.

A second life for rechargeable batteries

Once an EV battery begins to lose its capacity, it needs to be replaced. That doesn’t necessarily mean that the battery gets sent to the landfill, though. Many used batteries still have plenty of capacity for a “second life” application. For example, these used lithium-ion batteries often have more than enough capacity to be used to store energy generated by solar power or wind power systems.

To test the capacity of these batteries, you need a high-power output power supply that is capable of charging them to almost 100% and then discharging them again. The EA-PSB 10000 bidirectional power supply is perfect for this application. It can supply up to 30 kW in a 4U enclosure, making it the highest power density supply currently on the market. In addition, you can configure a rack system to supply up to 1.92 MW, which means that mass testing is also possible without any problems. And, the EA-PSB 10000 seamlessly switches between operation as a supply and as a load, which saves time during capacity testing.

The EA-PSB 10000 Series are also autoranging. This guarantees the maximum possible charge and complete discharge of the batteries because the supplies can source and sink high load currents even at voltages below 2 volts. The EA-PSB 10000 is also cost-effective because up to 96% of the energy absorbed by the load can be returned to the mains power source.

Safety and efficiency when fully discharging batteries

Of course, not all batteries are suitable for reuse. These batteries must be recycled. In the recycling process, they are disassembled, and some parts are discarded while others are re-used. Because lithium-ion batteries can be quite volatile, this process can be dangerous. To prevent the batteries from igniting, they must be completely discharged. This can be done with the EA-ELR 10000 regenerative electronic load, which is the most efficient instrument currently available.

Like the EA-PSB 10000 Series, the EA-ELR 10000 Series has a very high power density. It is capable of sinking up to 30 kW in a 4U enclosure and up to 1.92 MW in a rack system containing several units. These instruments can extract large amounts of residual charge from batteries in a short time and feed it back into the grid with an efficiency of up to 96% thereby reducing operating costs and protecting the environment. These efficient electronic loads also feature lower heat generation than other loads, meaning that expensive external cooling systems are usually unnecessary.

EA Power Control Software offers an intuitive interface

To run these tests, EA offers the EA Power Control operating software. Its user-friendly interface allows convenient and precise control of battery testing and discharge using a Windows PC. This software allows users to control up to 20 power supplies and electronic loads simultaneously, making it a highly efficient way to test and discharge batteries.

Re-using and recycling batteries will become even more of a challenge as electric vehicles become even more popular. Fortunately, we have the solutions that battery recyclers need. For more information on battery testing, discharging and simulation, visit the EA website, send an e-mail to sales@elektroautomatik.com, or call us at 858-836-1300.

To learn more about Regenerative Energy Recovery please click here.